RESEARCH

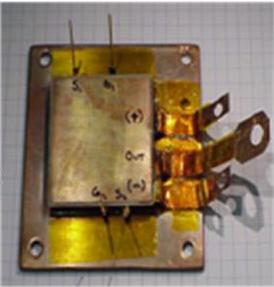

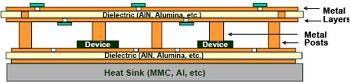

Metal-Post-Interconnect-Parallel-Plate-Structure (MPIPPS) (1999)

The new technology offers several potential advantages:

- The ability to conduct large current with negligible parasitic inductance and capacitance because of the short and thick metal posts that are used for the interconnections in the module;

- Better thermal management due to the additional thermal paths offered by the posts and the option of dynamic cooling with the use of a dielectric fluid flowing directly through the devices in between the plates;

- Ease of integration of the passive components because multiple plates can be readily stacked on top of one another through metal posts;

- Better reliability due to low thermal stresses with the use of identical plates for the circuit planes.