RESEARCH

Integrated EMI filter for HID ballast

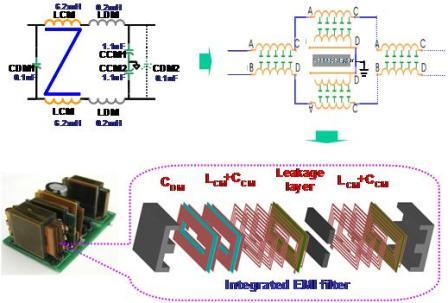

CM inductor and CM capacitor are functionally integrated with low-pass filter termination configuration. Since large CM inductance (several mH) requires a larger number of turns for the winding, while CM capacitance (several thousand pF) requires a relatively small copper area, a hybrid structure is used for this winding design. An embedded conductive layer is inserted to CM winding to cancel the equivalent parallel capacitor (EPC).

The leakage inductance between two CM windings serves as the DM inductance. An additional layer with low permeability magnetic material (LTCC 200) is inserted in between to increase the leakage inductance.

DM capacitors are implemented by integrated LC winding connected as capacitors, and four-terminal transmission line connection method is used to minimize equivalent series inductance (ESL) of DM capacitors.

Both the DM attenuation and CM attenuation of the integrated EMI filter are greatly improved at 10MHz~20MHz range compared with the discrete EMI filter. And the size of the integrated EMI filter is reduced by 41%.