LIBRARY

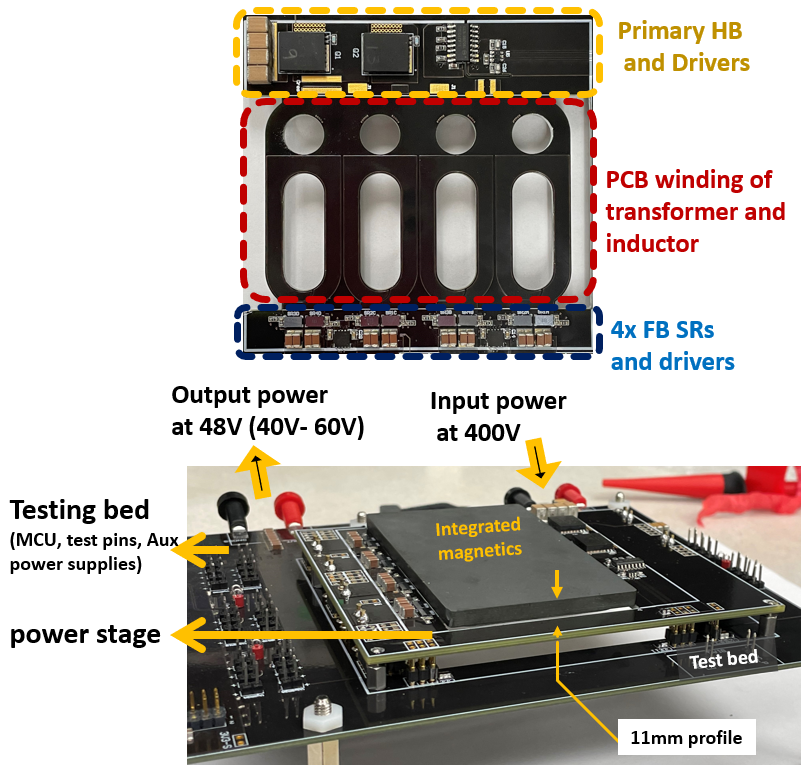

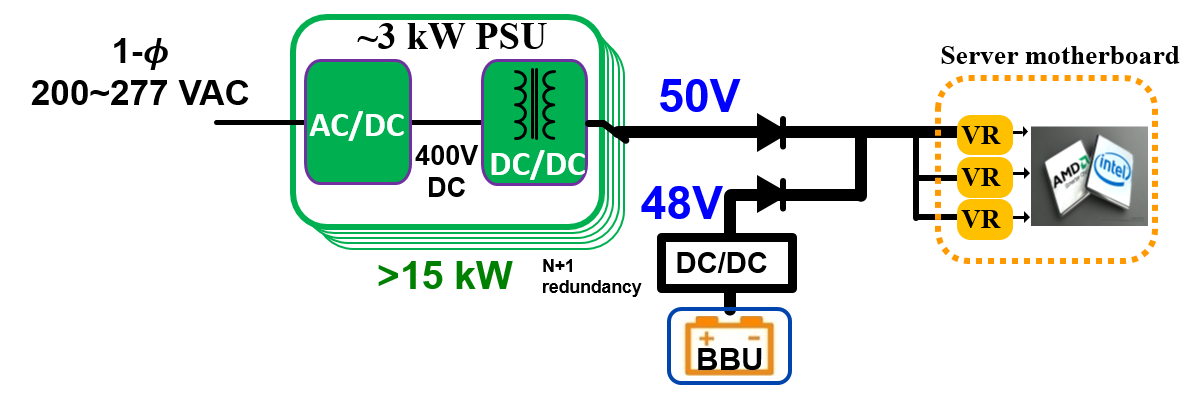

Low-Profile and High-Efficiency 3 kW 400 V-48 V LLC Converter with a Matrix of Four Transformers and Inductors for 48V Power Architecture for Data Centers

In this paper, high efficiency and low-profile design are proposed for the 48 V LLC converter for the data center. The converter utilizes PCB magnetics for better thermal management, easy assembly, and lower cost. The matrix transformer is optimized through multiple aspects. The number of elemental transformers is selected based on the required number of parallel SRs. The turns number of 2:2 per elemental transformer is found to achieve better light load efficiency compared to the 1:1 turns ratio as the core loss reduces. The switching frequency is optimized and 250kHz is found to have the least total converter loss given the selected devices and ferrite material. The matrix inductor concept is presented to reduce PCB inductor winding loss and reduce thermal stress on PCB. The matrix inductor concept helps to avoid the extreme increase in ac resistance due to the MMF build-up. The ac resistance is found to be reduced by a factor of 1/7 for the case of 4 turn inductor. The converter achieves 98.8% efficiency and 600 W/in3 power density. The converter has an extremely low profile of <11mm. This reduces the PCB-to-air thermal resistance and facilitates thermal management.