LIBRARY

Design of a 24 V, 1 MHz, 5 kW Partial Power Processing Converter and High Frequency Transformer for 80 C Ambient Using Flex PCB Technology

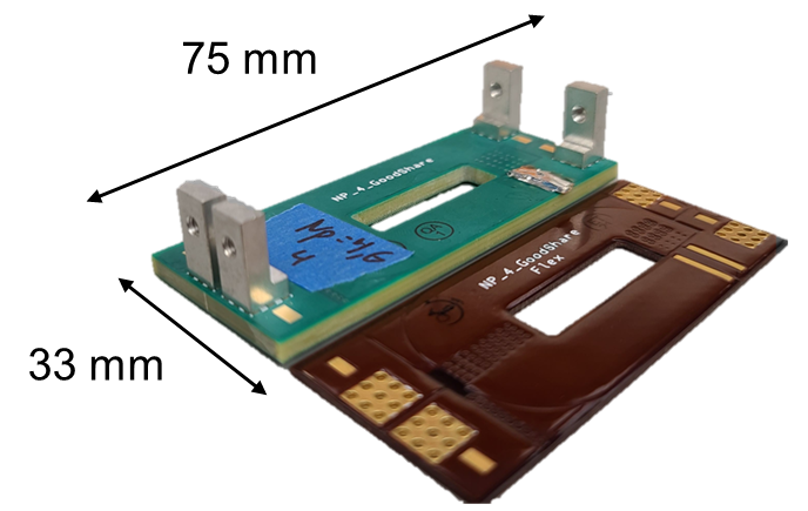

The PCB transformers constructed in this work are implemented in a 5kW, 1MHz, 360 -- 400Vin to 24Vout partial power processing converter. The majority of the power flows through a fixed-gain CLLC resonant converter that always operates at the resonant frequency, enabling zero-voltage switching (ZVS) and high efficiency to be achieved over the entire load range. A two-phase interleaved buck converter in series with the variable input is used to realize constant 24V output. Because a buck converter is used to set the input to the fixed-gain CLLC resonant converter, the converter uses simple proportional-integral (PI) control instead of complicated pulse-frequency modulation (PFM) control, which simplifies the design process and converter implementation. With ZVS occurring over the entire load range, the partial power processing topology shows improved EMI performance compared to conventional two-stage solutions. The converter achieves a peak efficiency of 98.5% at full load, 156 W/in3 power density, and is able to successfully operate at full load in an 80° C ambient environment with conductive cooling of the converter to a common chassis.

IMAGE1]