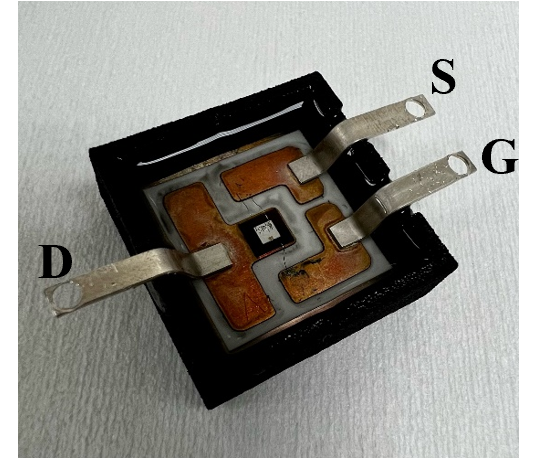

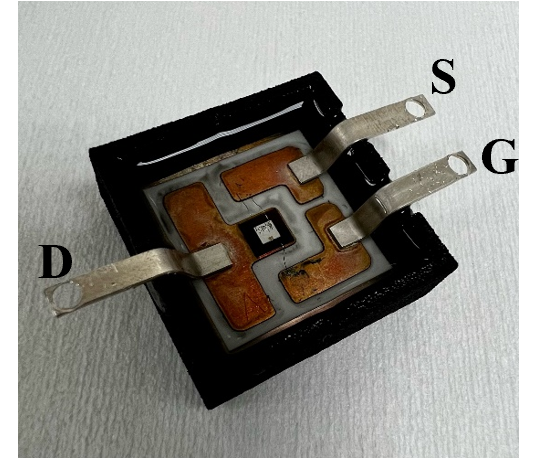

Fig. 1. A photo of one fabricated 15kV SiC MOSFET single-die package without lid.

Packaging of medium-voltage power semiconductor devices is challenging because the insulation materials must withstand extremely high electric-field (E-field) stresses as well as extract heat from the devices. To reduce the E-field stress at a TP (triple point), explored methods mostly focused on modifying the geometry of the substrate, including increasing the insulation thickness, stacking multiple substrates, protruded ceramic substrates, substrates with cavities, adding field plate, etc. However, these methods either add extra thermal resistance to the heat-extraction path of the package, compromising the thermal performance of the package, or require complex manufacturing processes, making them difficult for the industry to adopt. One way to enhance the insulation of a device or module package without trading its thermal performance is to apply a thin layer of nonlinear resistive coating along the triple points on the package's insulated metal substrate.

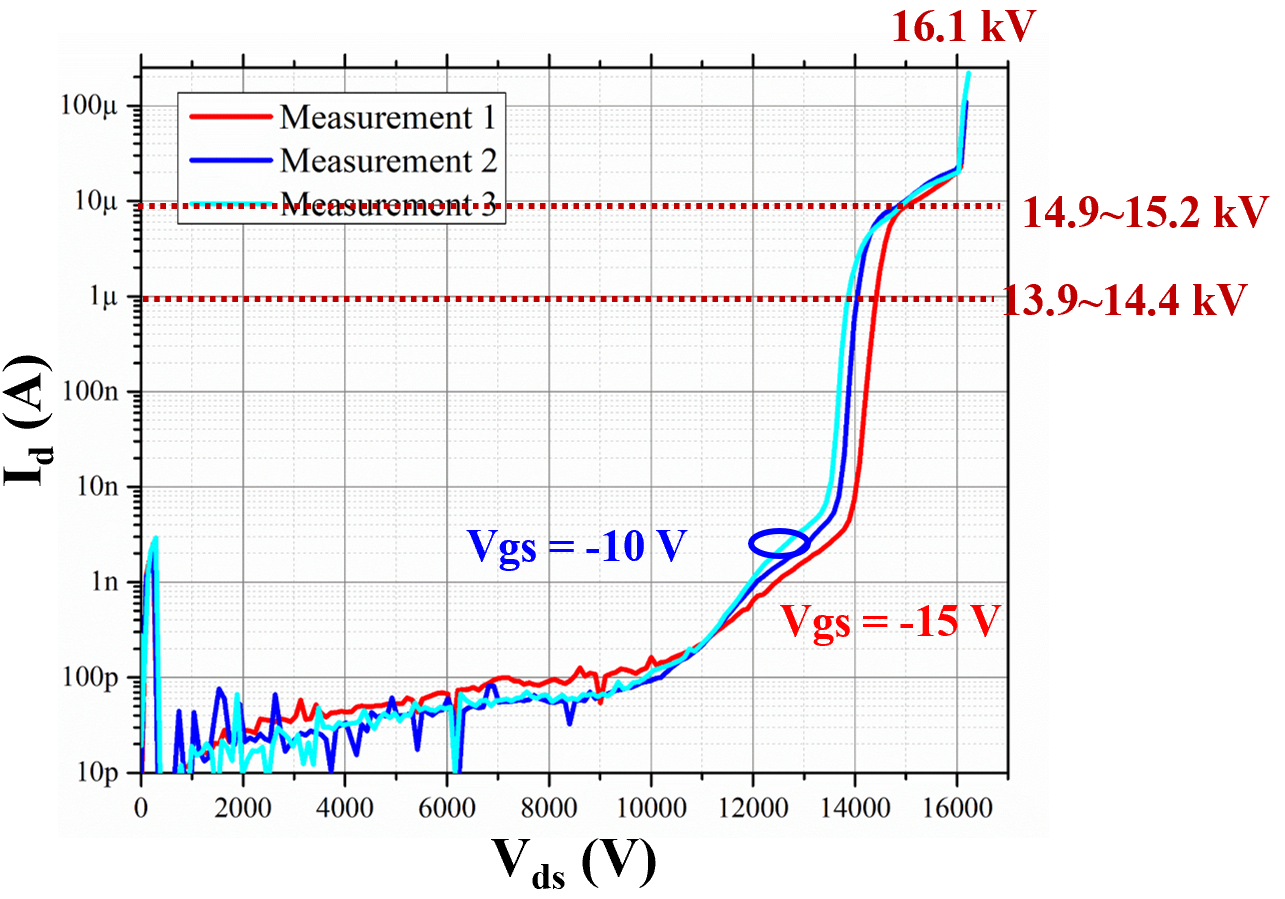

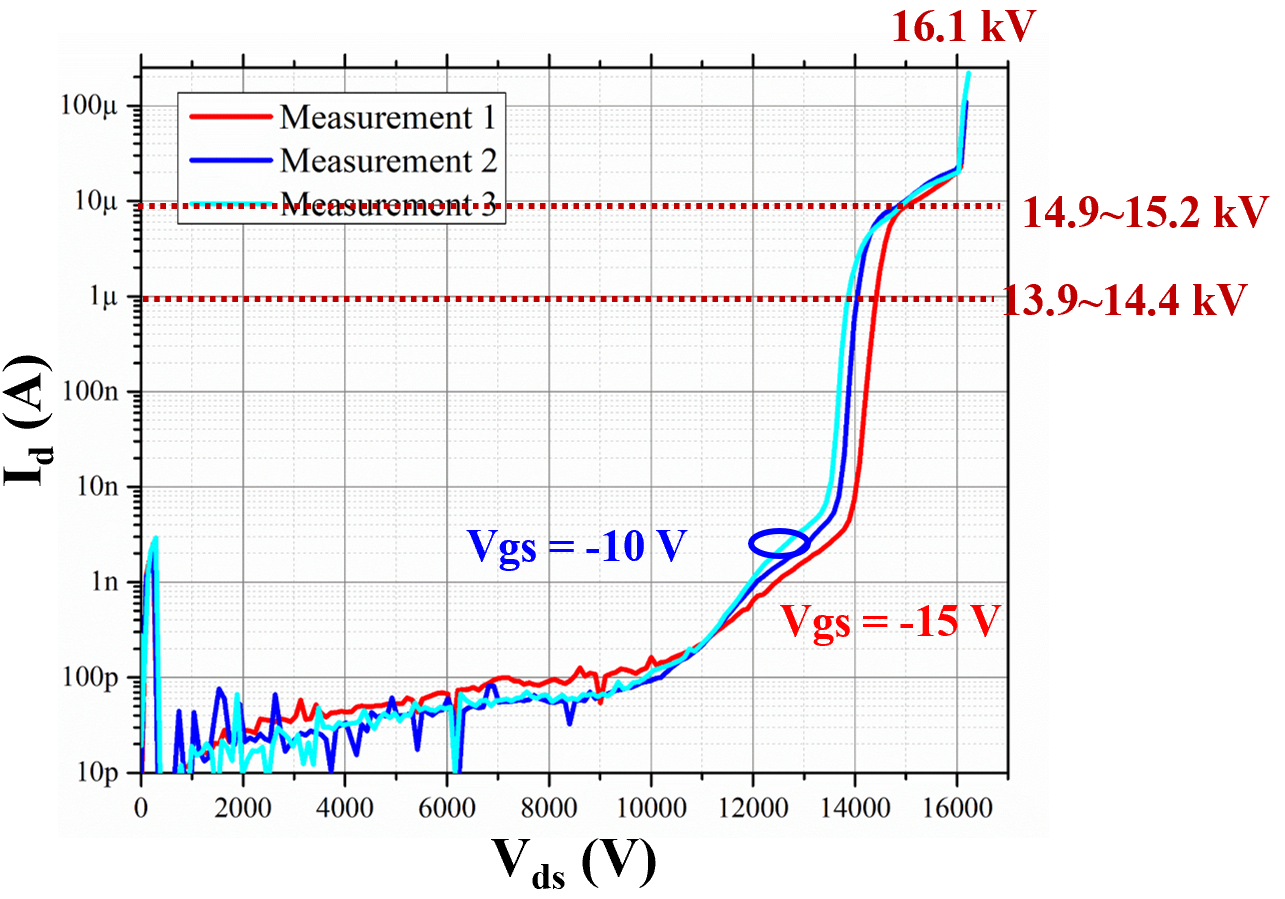

In this work, the packaging of a 15 kV silicon-carbide (SiC) metal-oxide-semiconductor field-effect transistor (MOSFET) was developed with the help of a nonlinear resistive polymer-nanoparticle coating applied along the copper edges of the package's direct-bond copper (DBC) substrates. Without the coating, the substrate -- a 1.0 mm alumina DBC substrate encapsulated in a silicone gel -- had an average partial discharge inception voltage of around 9.7 kV, 35% below the device's rated blocking voltage. With the coating, the partial discharge inception voltage was increased to 21.5 kV, a 120.5% improvement over that without the coating. Discrete 15 kV SiC MOSFET packages were fabricated on the coated substrates, as shown in Fig. 1, and their static electrical performances were characterized, as shown in Fig .2.

Fig. 2. Three consecutive measurements of the package's blocking capability.