LIBRARY

Effect of Sintering Temperature on Magnetic Core-loss Properties of a NiCuZn Ferrite for High-frequency Power Converters

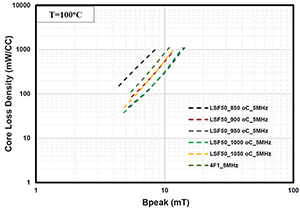

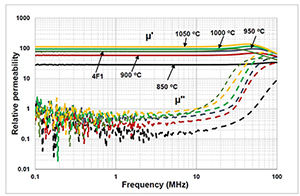

Fig. 1 shows plots of the frequency dispersions of the complex permeabilities obtained on the sintered LSF 50 cores and the custom-made NiZn ferrite (4F1) core. From the figure, the LSF 50 cores, except the one sintered at 850°C, had stable real parts of permeability beyond 10MHz; the real parts began to show the relaxation resonance phenomenon at around 30MHz. The real part (µ') of the permeability of the LSF 50 core sintered at 850°C was about 28, significantly lower than the others; however it remained stable over 70MHz. The imaginary parts (µ") of the permeabilities of all the sintered LSF 50 cores increased with sintering temperature and also had the resonance phenomenon at about 30MHz. Comparing the µ' and µ" traces of the NiZn (4F1) ferrite and those of the NiCuZn ferrites, we see that the NiZn ferrite had a µ' trace similar that of the LSF 50 sintered at 950°C; however, the µ"of the NiZn ferrite was significantly higher than that of the 950°C sintered LSF 50 ferrite over megahertz frequency regime. Fig. 2 shows the core-loss density plots measured at 5 MHz of all the sintered LSF 50 cores and NiZn ferrite (4F1) core that were submerged in a 100°C oil bath. The figure clearly shows that the sintered LSF 50 cores, except the one sintered at 850°C, outperformed the 4F1 core. The cores sintered at 950°C and 1000°C had about the same core-loss densities that were the lowest and were nearly two to three times lower than that of the NiZn ferrite.

A commercial NiCuZn ferrite powder doped with Bi2O3 was used to study the effect of sintering temperature on their magnetic properties, both the complex permeability and core-loss density, for applications in high-frequency power converters. The ferrite powder was sintered into toroid cores at 850, 900, 950, 1000 and 1050°C for two hours. We found that the sintering condition at 850°C for two hours was not sufficient to densify the powder, resulting in low relative permeability and high core-loss density. All the other sintered cores had relative permeabilities in the range of 60 to 115, which followed the trend of higher permeability with increasing temperature. The core-loss densities measured at 5 MHz and several to over 10 mT of B-field strength were the lowest from the cores sintered at 950°C and 1000°C. Comparing with the core-loss density of a commercial NiZn ferrite (4F1) toroid core, the loss densities of all of the sintered LSF 50 cores, except the one sintered at 850°C, were 2 to 3 times lower than that of the NiZn core. We believe that a combination of high density, large grain size, and high electrical resistivity of the sintered LSF 50 core contributed to lowering the eddy current loss and hysteresis loss under the 5 MHz alternating magnetic field excitation.