LIBRARY

Design and Additive Manufacturing of Multi-Permeability Magnetic Cores

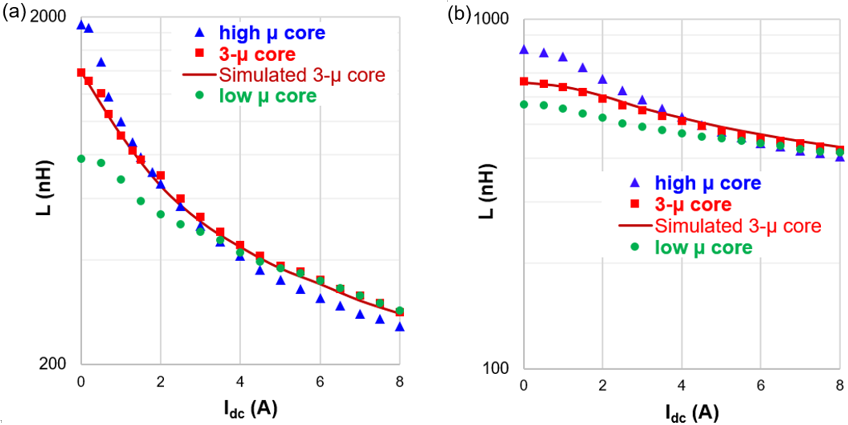

For comparison, two single-permeability toroid cores for each magnetic system were made: one with the lowest permeability paste, and the other with the highest. These have the same dimensions as their corresponding three-permeability cores, and were created using a 3D printer. To test the cores, all were wire-wound into inductors. The same number of turns was used for each magnetic system. Fig. 2 (a) shows the L-Idc plots of the ferrite inductors. The initial inductance of the three-permeability inductor was lower than that of the single-permeability of the 70 inductor, due to its lower average initial permeability, but higher than that of the single-permeability of the 30 inductor. With the increase of dc current, the inductance of the three-permeability core decreased at a slower rate than that of the 70-permeability inductor, and became higher at dc current greater than 1.7 A. The inductance of the three-permeability inductor was always greater than that of the 30-permeability inductor over the entire range of dc bias.The L-Idc plots of the powdered iron inductors are shown in Fig. 2 (b). As described in the previous paragraph, there is a similar behavior of the inductance versus dc bias exhibited by the powdered iron as those by the ferrite.

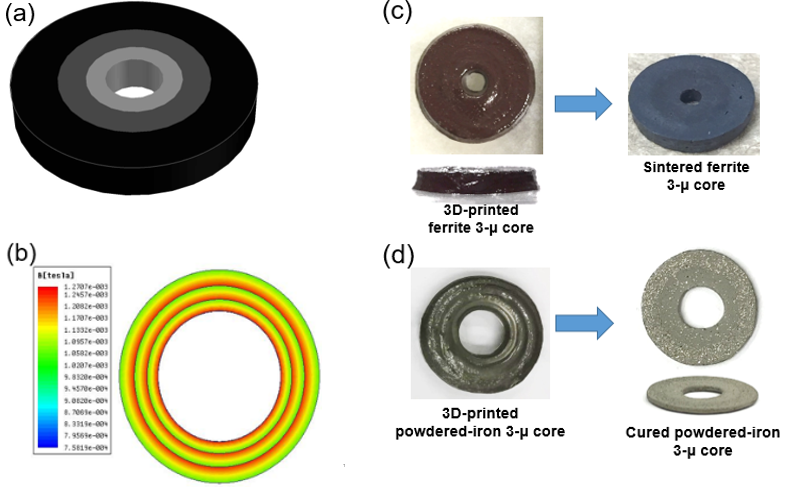

An additive manufacturing method for fabricating multi-permeability magnetic cores in order to achieve more uniform magnetic flux distribution was presented. The printing platform is based on a commercial multi-extruder 3D printer to process magnetic pastes with different compositions into 3D structures. Two paste systems were developed, a high-temperature (greater than 900° C) pressureless sinterable ferrite and a low-temperature (less than 250° C) pressureless curable powdered iron. Both were shown to be compatible with the 3D printer and can be processed into cores with a wide range of relative permeabilities. For each magnetic material system, a three-ring toroid core was designed and 3D printed. Characterization of inductance versus dc current showed that multi-permeability inductors can significantly increase inductance density under dc current bias over inductors made with a single-permeability material.