LIBRARY

Gate-driver Integrated, Junction Temperature Estimation of SiC MOSFET Half-bridge Modules

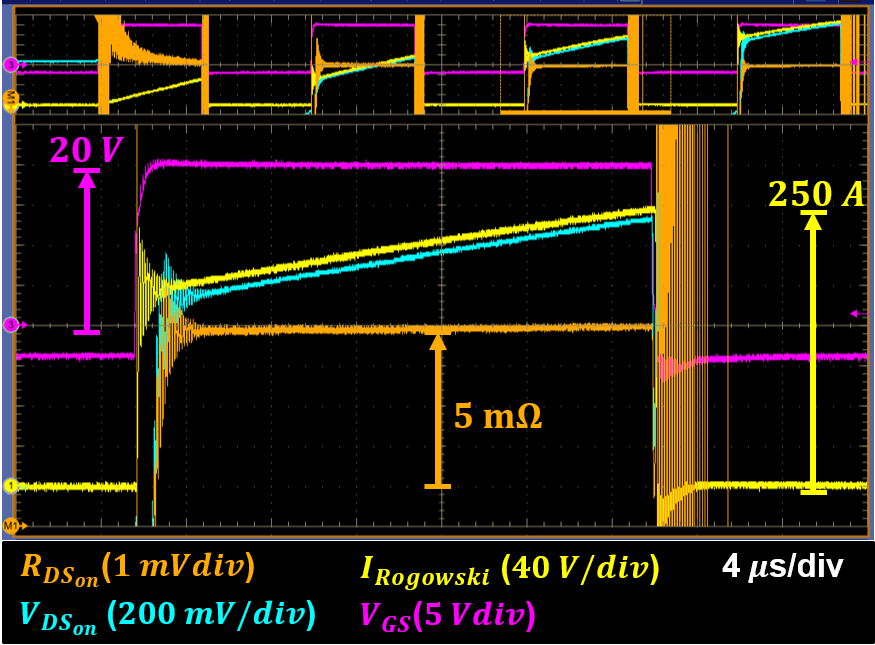

Taking all of this into account, an intelligent gate driver is developed, containing the described measurements. A stacked gate driver is shown in Fig. 1. with the indicated controller part of the gate-driver, the actual driver board, Rogowski coils for switch current measurement, and a utilized circuit for on-state voltage measurement. A 2-diode circuit is employed as an on-state voltage mea- surement sensor, due to benefits it has over similar circuits utilized in the literature, including high blocking capability, no offset prob- lem, non-temperature-dependent sensing diode circuit, low delay, small losses, good accuracy and sensitivity. These benefits render it perfectly suitable to be used in combination with a Rogowski coil and have accurate on-state resistance and thus junction temperature estimation. Fig. 2. shows initial Rds,on measurement results. Online junction temperature estimation will be performed with the aid of a field programmable gate array (FPGA) that will sample current and voltage information at the same time. Based on the pre-characteriza- tion results of the device stored in the flash memory (current, voltage and temperature look-up table) located on the controller board of the gate driver, FPGA will assess and compare voltages and currents, as well as estimate junction temperature.