RESEARCH

Integrated Modular Motor Drive (IMMD)

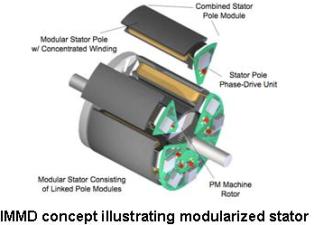

Modular phase-drive units offer opportunities for standardization and high-volume production to reduce future drive costs. The use of simple concentrated windings eliminates the need for expensive winding machines to "sew" windings into the slots of conventional motors. The risk of short circuits between windings is dramatically reduced since the windings no longer overlap each other, minimizing any direct contact between the phase windings. In addition, the modularity of the IMMD makes it possible to design the motor drive to continue operating when one or more of the phase-drive units fails, improving overall drive reliability.

Several technology innovations contributed by CPES multi-disciplinary teams are planned for incorporation into the IMMD, including the elimination of electrolytic capacitors and the use of integrated current and temperature sensors inside the IPEMs. Based on these advances, the IMMD architecture is being aggressively pursued as the template for future generations of low-cost, robust motor drives.