RESEARCH

Integrated ignitor for HID ballast

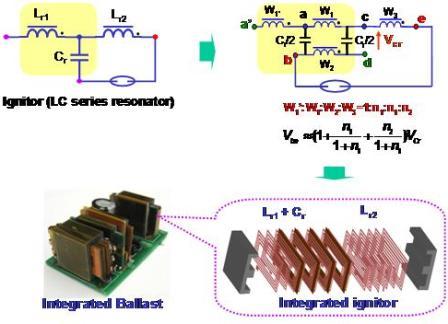

In discrete implementation, one inductor and one capacitor form the series resonator. An additional coupled winding is added to further boost the voltage for ignition purpose. In the integrated implementation, the resonant inductor and capacitor are functionally integrated into one module. Stacking two planar spiral windings and inserting a dielectric substrate in between forms a four-terminal integrated LC unit. The distributed structural capacitance is utilized as the resonant capacitance. By proper termination, the structure functions as a series resonator.

In order to achieve proper capacitance value (several hundred pF) and withstand high igniton voltage (3kV~4kV at lamp), kapton with low permittivity (εr≈3.5) and high dielectric strength (137 kV/mm) is selected as the dielectric substrate.

Since the conductor area required by the inductor is much more than that for the capacitor, the integrated resonator is implemented with the hybrid structure.

The integrated resonator is implemented by four layers of Pyralux windings with double-sided copper layers and two layers of pure copper windings. The additional coupled winding is a six-layer pure copper winding, which can be made of PCB winding. The size of the integrated ignitor is reduced by 48% compared with the discrete implementation.