RESEARCH

Nanoscale material technology for interconnecting semiconductor devices with high heat dissipation and high temperature capability

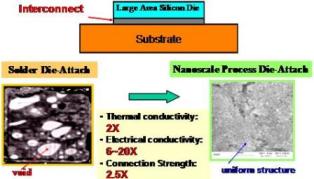

CPES's lead-free nanomaterial attachment possesses better thermal, mechanical, and electrical properties than soldered or epoxied attachment. The low-temperature sintering process is also completely compatible with existing equipment and facilities that use solders or epoxies. Using CPES's material and process, high power-density semiconductor electronic or optoelectronic devices can be operated at high temperatures in excess of 250°C, not attainable with any existing solder-based die-attach and epoxy materials.

The patented technology is expected to achieve 2 times improvement in thermal conductivity, over 6 times improvement in electrical conductivity, and 2.5 times improvement in connection strength.

This technology has inspired the founding of NBE Technologies, LLC, a start-up company established by CPES-VT faculty member, Prof. Guo-Quan Lu. The company recently received financial support from the Running-Start fund managed by the Corporate Research Center (CRC) of Virginia Tech. With this support, NBE is constructing a production facility in the VT KnowledgeWorks building, a business incubation cradle at the CRC. NBE specializes in the manufacturing of nanoscale materials for electronic packaging and biomedical applications. Its nanoscale die-attach materials are being evaluated for possible use by several large manufacturers of power electronics devices and modules.