RESEARCH

Over-Molded Inductor (OMI) - Feasibility Demonstration in a DC-DC Converter

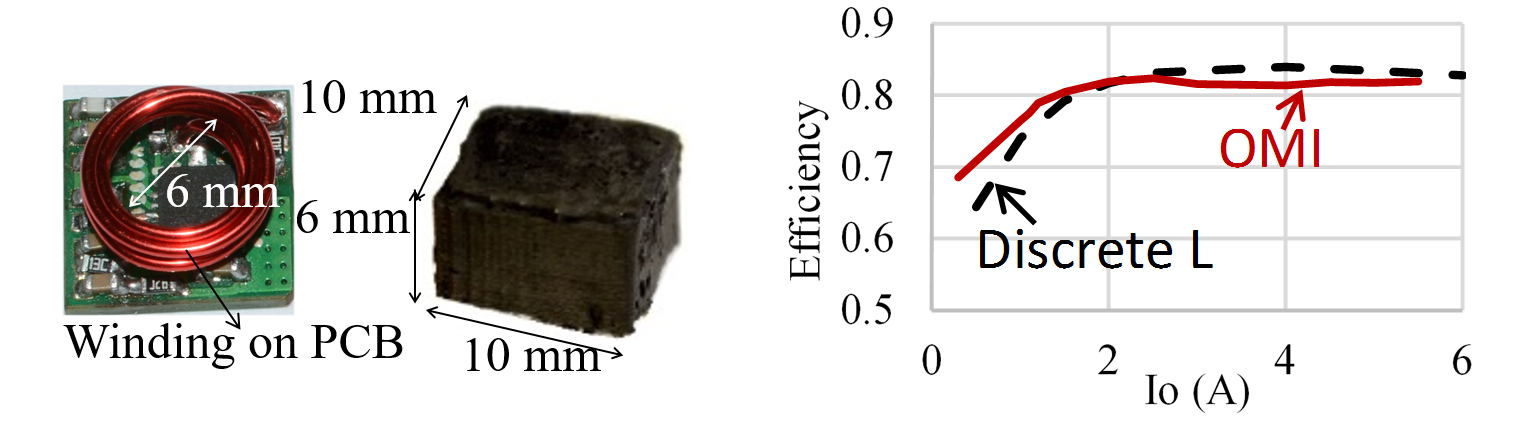

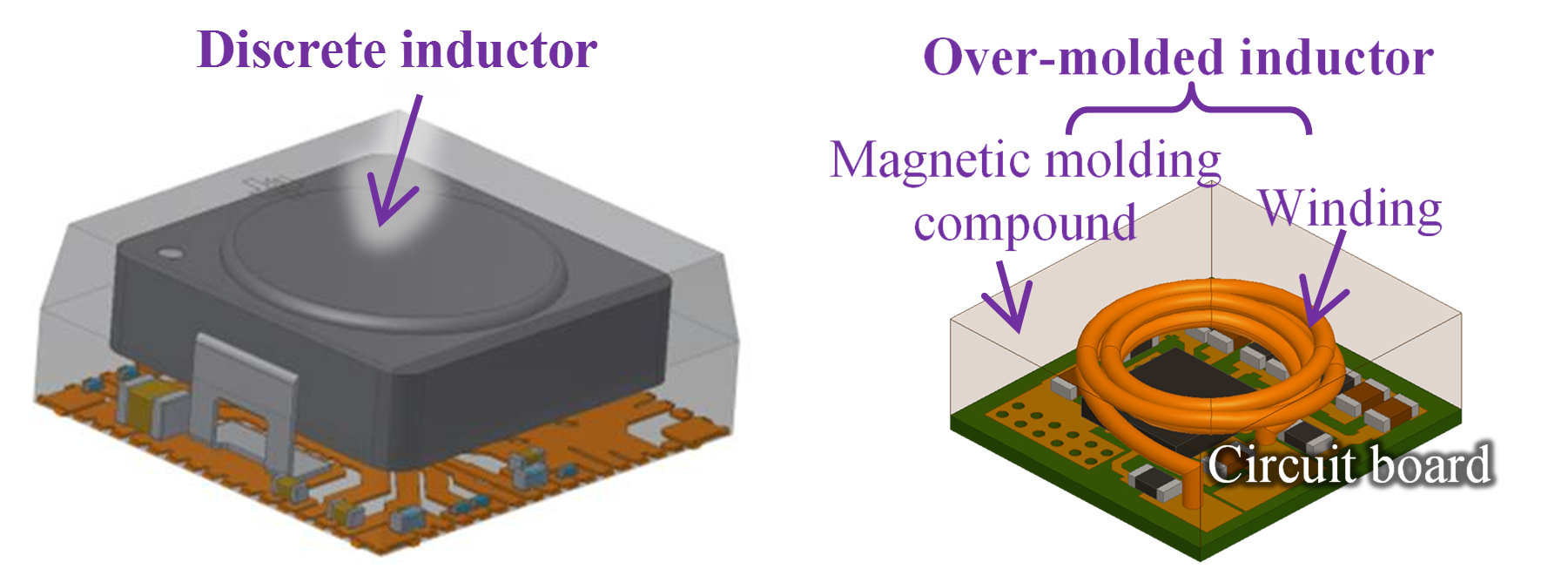

This paper presents an alternative to inductor fabrication called "over-molding." As depicted in Fig. 1(b), the winding is first attached to the substrate. Magnetic paste is then injected into the unused space that is normally occupied by encapsulant and is cured under atmospheric pressure below 250 °C to realize the core. The prototype of the OMI is shown in Fig. 2(a).

The impact of the OMI on the converter's efficiency (Fig. 2(b)), operating temperature, and switching noise was demonstrated to be similar to that of the commercial inductor. Also demonstrated was the feasibility of storing magnetic energy in the volume normally filled by encapsulant. The next goal would be to improve the power density, which is tied directly to permeability. The materials and fabrication process will be examined to improve the homogeneity of over-molded magnetic mixtures using a low curing temperature under atmospheric pressure.