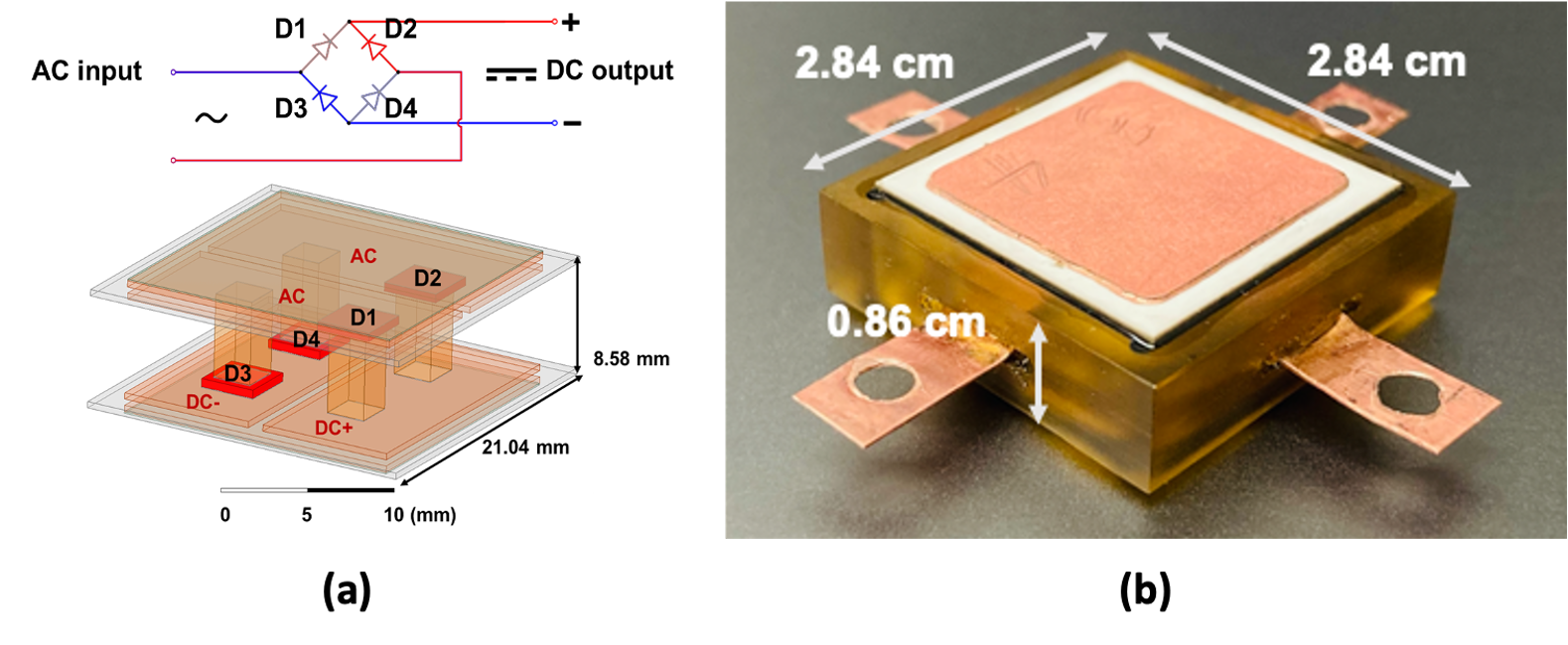

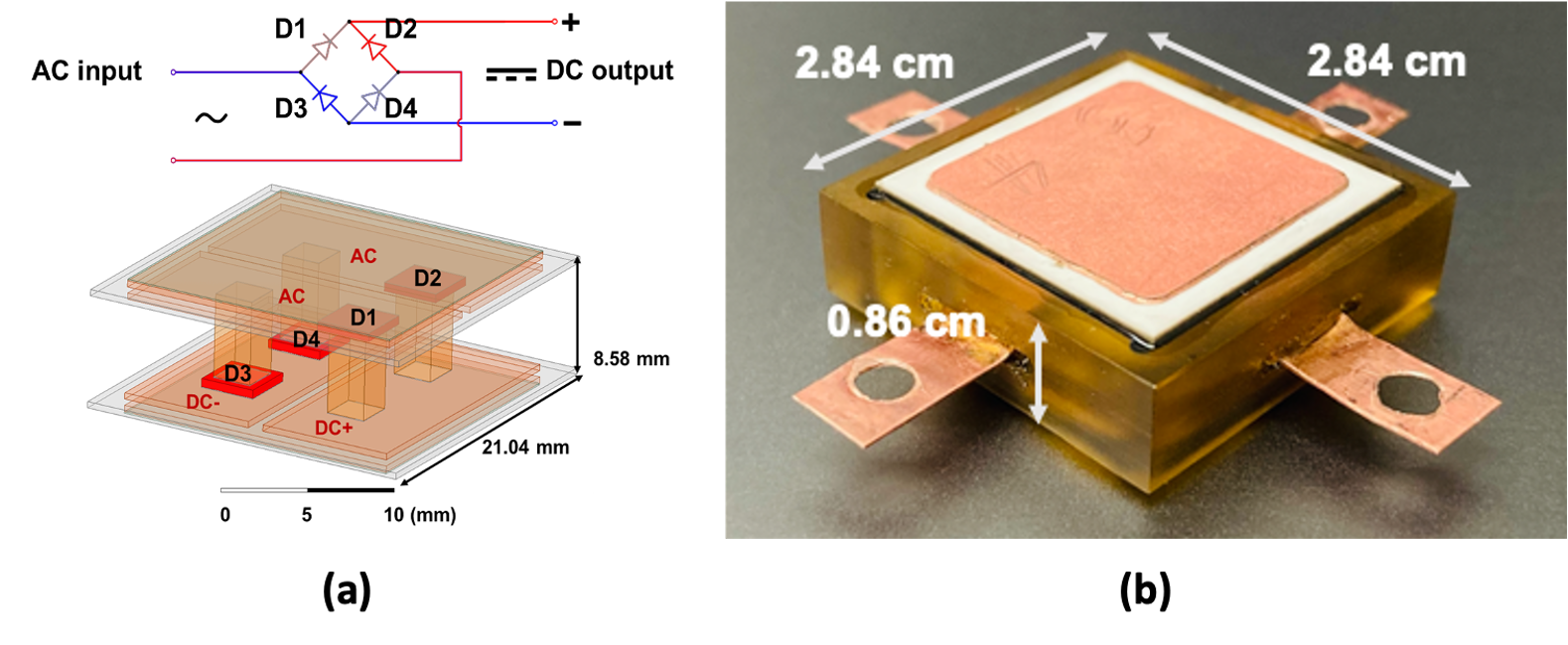

Fig. 1. SEQ Fig.1 (a) Schematic of the double-side cooled 8-kV SiC diode full-wave module and its equivalent circuit. (b) Prototype of the 8-kV SiC diode full-wave rectifier module.

The power-handling capability of a packaged power semiconductor device is limited by the heat extraction ability. The heat extraction pathway involves conduction from junction to case, and the heat transfer from case to the coolant. A unique challenge for packaging MV power modules is the trade-off between the heat extraction and the insulation. Two packaging innovations that can improve heat extraction without compromising insulation, thus expanding the safe operating area of the device and reducing the number of devices needed for a specific application, are (1) double-side cooling and (2) sintered-Ag bonding. The first is realized by using short metal posts, rather than long and thin wire bonds for device interconnection, to form a low-profile package with devices sandwiched between two insulated metal substrates. The second enables the devices to function reliably at device junction temperatures over 250(°) C, which is higher than that of the state-of-the-art soldered power devices. The latter innovation is especially significant for packaging wide bandgap devices since these devices theoretically can function at much higher temperatures than silicon devices.

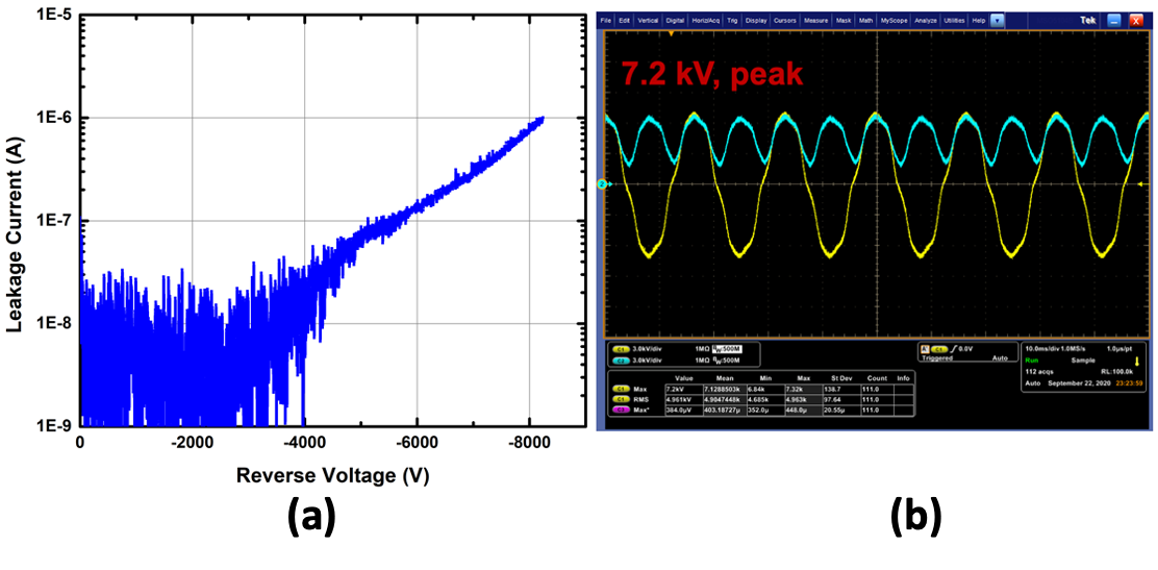

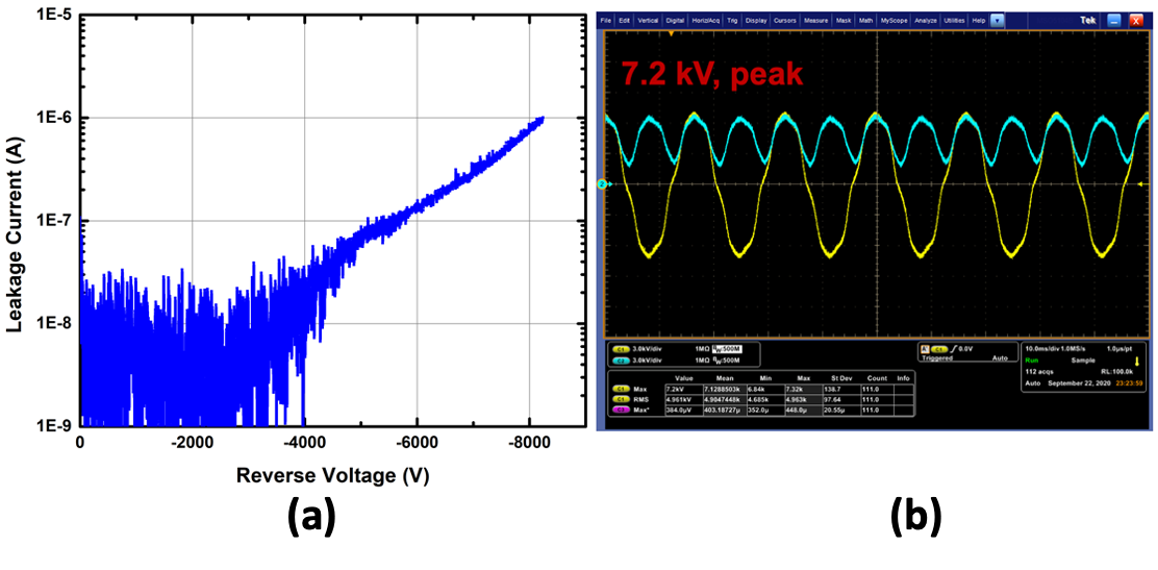

In this work, we implemented the two packaging innovations for the design and fabrication of an 8-kV SiC full-bridge diode rectifier module. Fig. 1(a) is a schematic of the module layout. The device chips were sandwiched between two patterned direct-bond-copper (DBC) substrates. Die-attach and metal-post bonding were done by silver sintering. Steady-state thermal simulations were run to verify the benefit of double-side cooling. Electrical and electric field simulations and analyses were performed to minimize the loop inductances and guide the insulation design. The packaging concept was implemented in assembling an 8-kV SiC diode full-wave rectifier shown in Fig. 1(b). The electrical testing results of the module shown in Fig. 2, validated the package design and fabrication.

Fig. 2. (a) Reverse I-V characteristics of Diode 4 (labeled in Fig. 1(a) as D4) after packaging. (b) Output dc waveform (blue) under 60 Hz sinusoidal ac input (yellow) with a 7.2 kV peak value.