LIBRARY

Characterization of a Nonlinear Resistive Polymer- Nanoparticle Composite Coating for Electric Field Reduction in a Medium-Voltage Power Module

Previously, we completed a simulation study to find the desired properties of a nonlinear resistive material for reducing the E-field intensities at the triple-point (TP) edges on a direct-bonded copper (DBC) substrate. The study was aimed at providing a guideline for materials engineers to develop effective field-reduction materials.

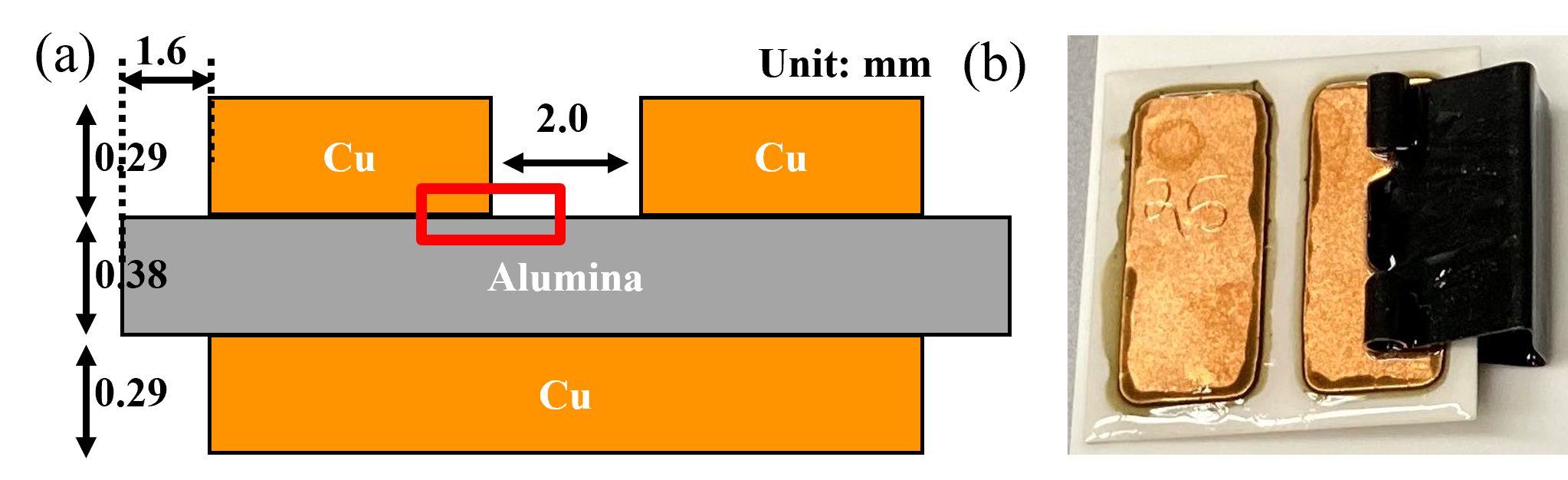

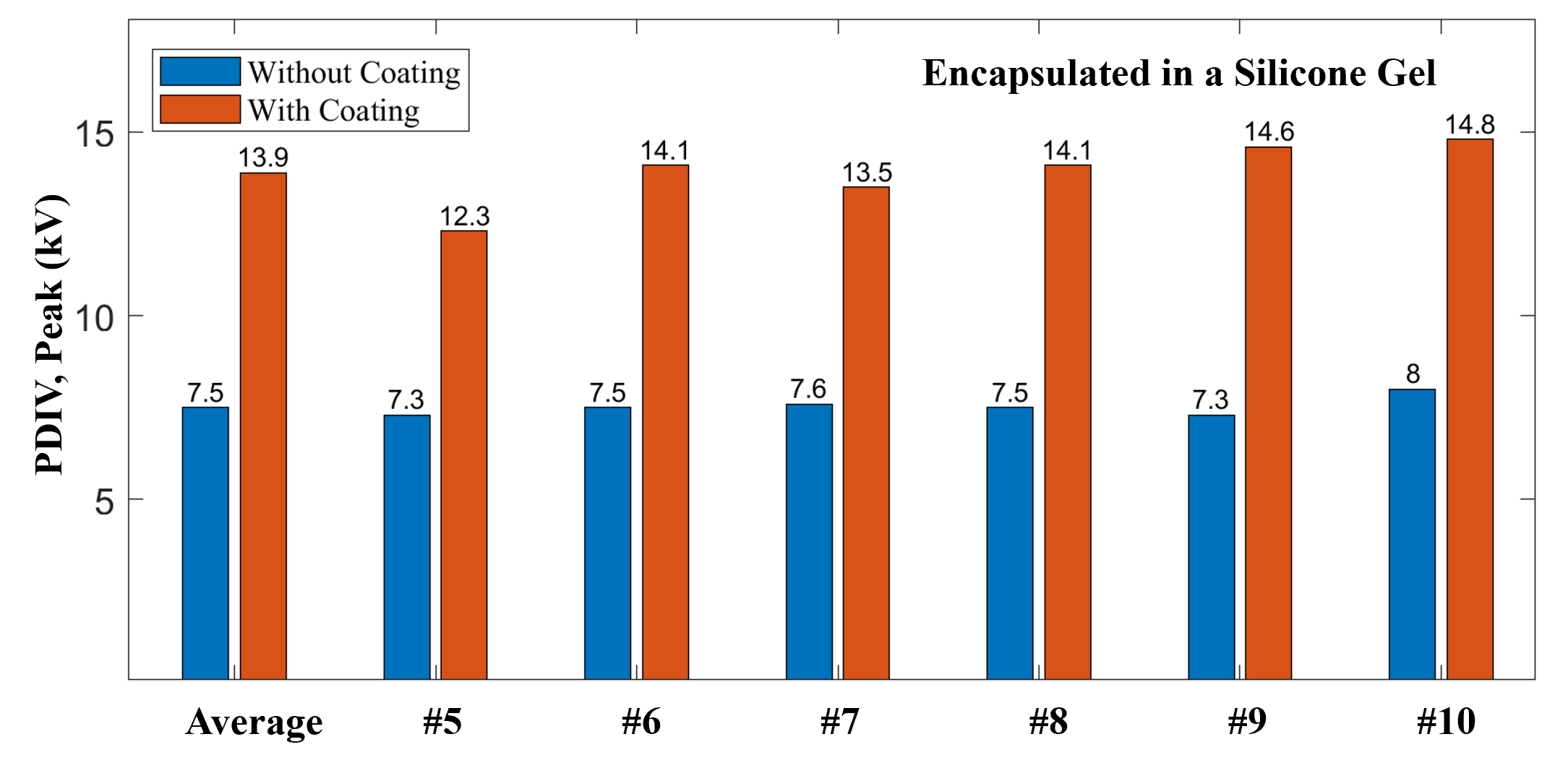

In this work, a polymer-nanoparticle composite material was characterized as a field-reduction coating of the triple point on a medium-voltage power module substrate. The electrical conductivity of the material showed nonlinear dependence on the E-field intensity with a switching field at around 15 kV/mm. Patterned DBC substrates, as shown in Fig. 1, with their triple points along the edges of the electrodes were coated by about 20 µm thick of the material, and their PDIVs were measured in a silicone gel. The coating increased the PDIVs of the substrates by over 85 % in the gel, as shown is Fig. 2. The significant increases in PDIVs of the coated substrates obtained in the gel were found to be in good agreement with the simulated reduction of the maximum E-field intensity in the gel. Our findings offered an experimental validation of a practical nonlinear resistive material for E-field grading in MV power modules.