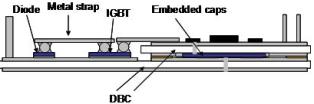

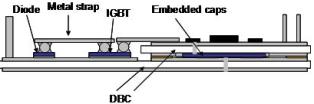

Fig. 1. Schematic of the cross-section of the package with the metal strap interconnections on the power devices.

CPES is actively developing integrated power electronics modules (IPEM) such as the Standard Cell IPEM (SC-IPEM) for next-generation power electronics systems. Various packaging and interconnection schemes have been developed and investigated, including MPIPPS, flipchip on flex, dimple array and embedded power. A key issue in the development of modules is the reliability of the interconnection scheme used. Compromises are usually made to accommodate the electrical requirements to the detriment of mechanical integrity. FlexPower was conceived to help alleviate potential problems with packaging schemes where the joints are exposed to stresses due to CTE mismatches among the packaging materials and devices. With FlexPower, the top of the mounted devices (IGBTs and diodes) are interconnected by flexible metal straps. The straps can be plain Cu or Cu plated with Ag (or Sn). The joints to the devices are formed by reflowing solder to form an hourglass shape with the height controlled by a high-temperature solder ball in the middle. The increased height and hourglass shape of the joint, and flexibility of the straps will enhance reliability. The joints are relatively easy to fabricate as the procedure follows traditional joining processes. The technique is also conducive to automation in manufacturing.

FlexPower also provides a technological route to high-temperature packaging because the devices will be attached to the substrate using nanosilver paste, a material developed at CPES which has a higher operational temperature than most solder alloys. The silver will not melt until the temperature exceeds 960°C. Because the die-attachment is obtained through sintering - not a reflow or melting process - with a peak temperature of 300°C or lower, it is possible to substitute the solder components with the nanosilver paste without undoing the previous attachments in subsequent firing steps, something one has to guard against when using an all-solder solution. An added benefit of using nanosilver in conjuction with FlexPower is the higher electrical and thermal conductivities of the sintered nanosilver joints on the devices.

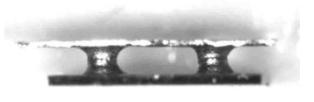

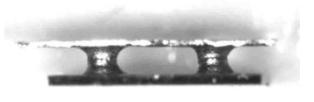

Fig. 2. Cu metal strap attached to an IGBT with solder balls and reflowed solder.