LIBRARY

Automatic power module layout design

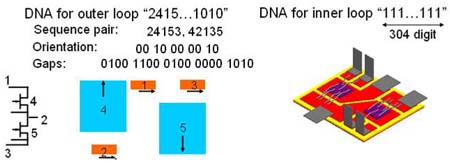

The power module layout design is an iteration-based comparison with a much smaller number of components and simpler placement and routing. However, unlike the fitness evaluation in the VLSI design, power module layout design requires a parasitic parameter extraction process. Based on these characteristics, the genetic algorithm (GA) is chosen as the automatic design algorithm. As shown in Figure 1, in the automatic layout design, there are two loops utilizing GA. The outer loop is the placement loop, in which the components are placed and evaluated based on the design results of the inner loop, which is the routing loop. The outer loop provides the layout of the components in the inner loop. With certain components positioned, the inner loop physically connects the components based on the electrical connection. The routing process is implemented by GA, and an analytical equation-based parasitic parameter calculation method is utilized during the fitness evaluation step. After several iterations, the best individual routing result and its fitness is passed on to the outer loop. The outer loop uses these routing results as the criteria for fitness in placement evaluation.

In the example studies shown in Figure 2, the best solution found through manual design is similar to that found with automatic design. Design results are also verified by Ansoft Q3D. The design results prove that automatic design has advantages in power module layout.