LIBRARY

Thermo-Mechanical Reliability Investigation of Large Temperature Excursions in Power Electronics Packages

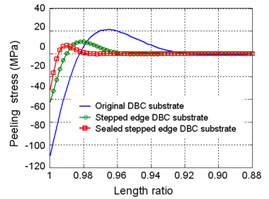

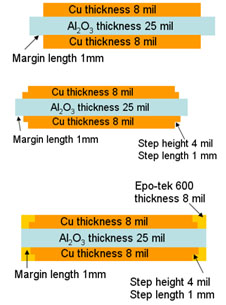

As seen in Fig. 2, the peak tensile peeling stress was verified by simulations and experiments as the major driving force of delamination. It is therefore the basis for improving the design and optimizing the process parameters so that power modules can have a high resistance to large temperature excursions.