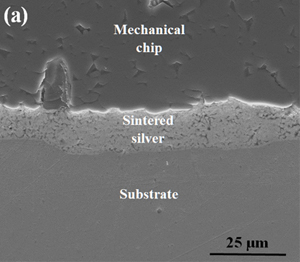

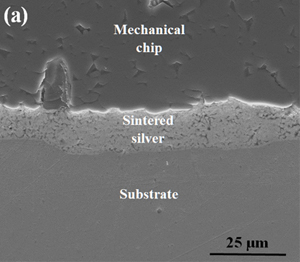

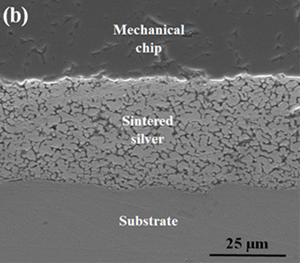

Fig. 1. SEM image of cross-sectioned silver attachment layer sintered by (a) nanoTach silver paste and (b) Ablestik SSP2000 silver.

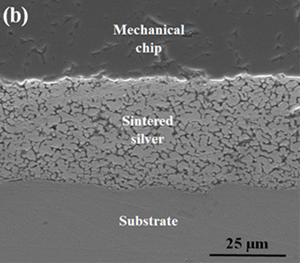

Two different brands of silver pastes, nanoTach and Ablestik SSP2000, were used to demon-strate the low-temperature joining technology (LTJT) by silver sintering for die-attachment. In this study, the bonding qualities such as the void percentage of attachment layers and die-shear strength, are evaluated. X-ray images of the sintered nanoTach and Ablestik SSP2000 silver layers show that the void percentages were 2% and 1%, respectively. It indicated that the coverage of these sintered silver layers was much better than traditional solder layers, of which void percentages were around 15%. The die-shear strength of nanoTach sintered die-attachments was 29.8±5.7 MPa, and that of Ablestik SSP2000 sintered die-attachments was 15.7±4.0 MPa. Comparing to traditional solders, nanoTach silver paste offers a comparable bonding strength, and Ablestik SSP2000 silver paste offers a lower bonding strength. The microstructures of sintered silver in the attachment layers are also studied in order to further understand the performance of sintered silver attachments. As shown in Fig. 1 (a) and (b), both the cross sections and failure surfaces of the sintered silver layers by nanoTach and Ablestik SSP2000 exhibit porous structures. Using SEM, the thicknesses of sintered silver layers are measured. The nanoTach and Ablestik SSP2000 silver pastes shrank 62% and 28% in thickness, respectively. The higher shrinkage of the nanoTach silver paste leads to a higher relative density in the sintered silver layer when compared to the Ablestik SSP2000.

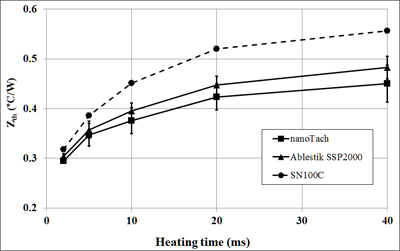

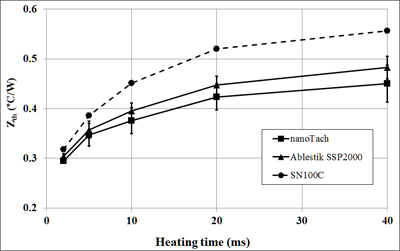

The microstructures of failure surfaces of nanoTach sintered silver show remarkable plastic deformation regions, which coincides with the die-shear testing results that show that the nanoTach sintered silver layers have a higher strength than the Ablestik SSP2000 sintered silver layers. Other than die-shear strength, the measurement of the transient thermal impedance shows that when compared to the SN100C solder die-attachments, the nanoTach and the Ablestik SSP2000 sintered silver die-attachments exhibit 18% and 13% lower thermal impedance with a 40 ms heating pulse, respectively.

Fig. 2. SEM image of cross-sectioned silver attachment layer sintered by (a) nanoTach silver paste and (b) Ablestik SSP2000 silver.

Fig. 3. Thermal impedance of samples with different die-attach materials.