LIBRARY

Effects of Boost Inductor on DM Noise of PFC

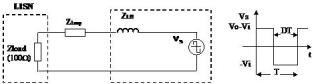

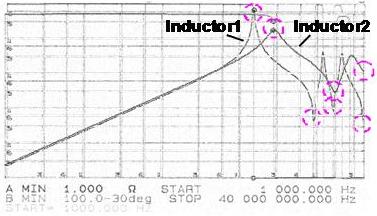

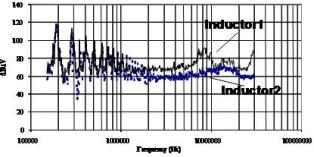

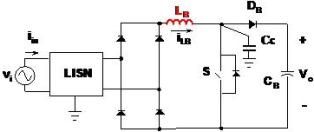

CPES has investigated the effects of boost inductors on the DM noise of boost PFC converters. Both theoretical analysis and experimental results show that the impedance of boost inductor significantly affects the DM noise of boost PFC. Theoretically, the main switch can be modeled as a noise voltage source. DM noise flows through boost inductor, one power line, line impedance stabilization networks (LISNs) and then flows back via the other power line. The boost inductor is therefore in the DM noise path. Since the impedance of boost inductor is higher than those of LISNs and power lines, it shapes the spectrum of DM noise. The higher the impedance, the lower the DM noise is. The inductance of the boost inductor is determined by the converter design. As a result, the impedance of the boost inductor is determined by the converter design at low frequencies. At high frequencies, the parasitics, such as the winding capacitance of the inductor, determine the impedance of the inductor. Reducing the effects of parasitics so as to increase the impedance of the inductor is a key to reduce HF DM noise. Impedances of two inductor designs are compared below. The PFC's DM noise curves with the two inductors are also compared below. It verified that higher HF impedance, which is due to the smaller parasitics and higher loss, leads to lower HF DM noise. Carefully boost inductor design is thus very important to reduce HF DM noise.