LIBRARY

High Density Integration of High Frequency High Current Point-of-Load (POL) Modules with Planar Inductors

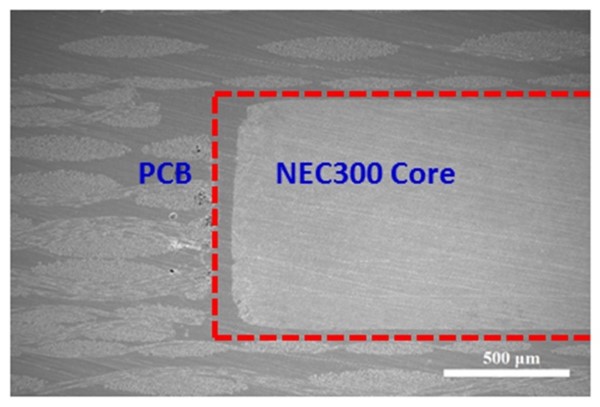

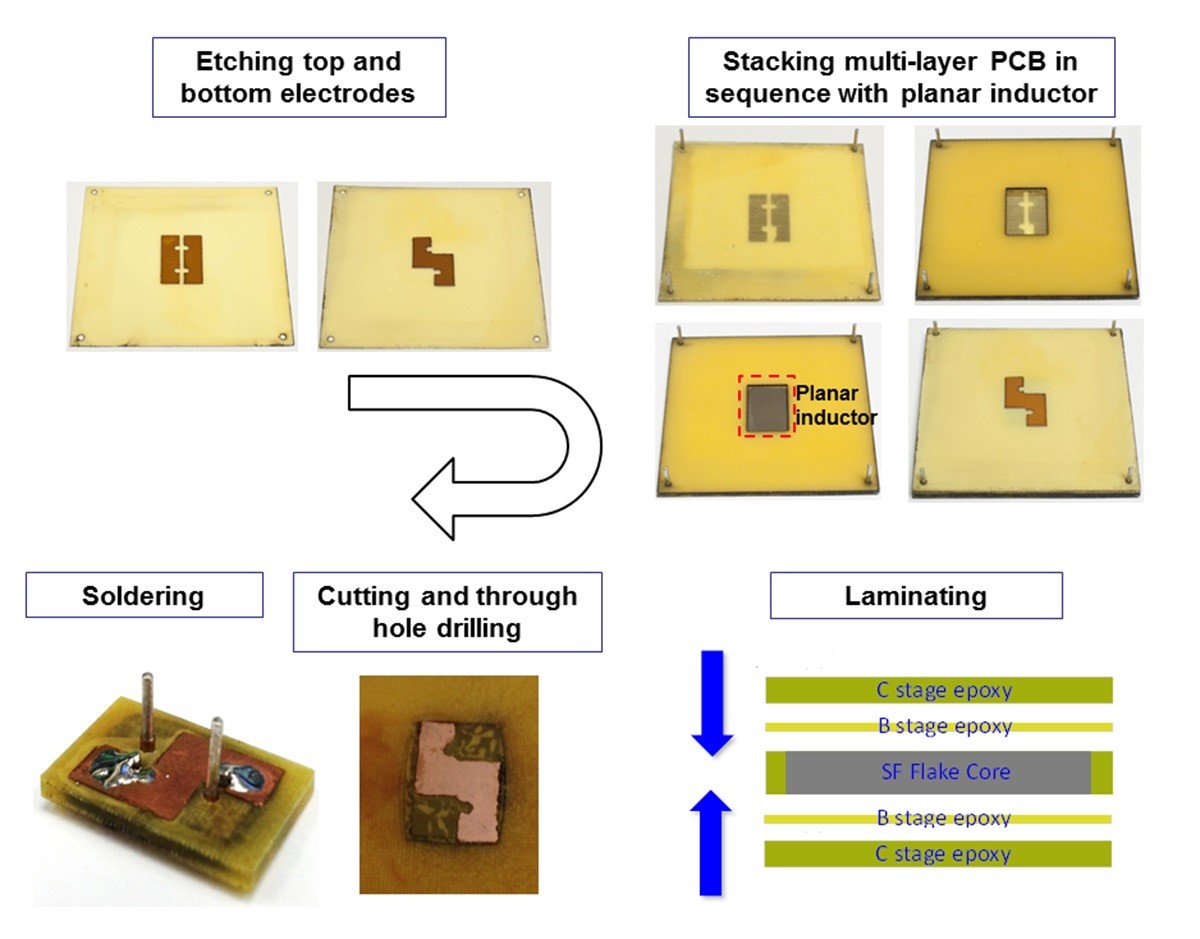

Planar inductors made by mixed laminates of low-temperature sintered Ni-Cu-Zn ferrite tapes and metal-flake composite materials are used for high density integration of point-of-load (POL) modules. Incremental permeability and core loss density were characterized on toroidal samples under high dc bias to demonstrate that both materials are suitable for application in high frequency high current POL converters. In order to realize a high power density POL module, a multilayer ferrite inductor laminated with alternating layers of ESL 40010 and ESL 40012 in a 1:1 ratio was fabricated and integrated with the active layer. Meanwhile, standard printed circuit board (PCB) processing was adopted for the POL integration with a PCB-embedded inductor using NEC-TOKIN's metal-flake composite materials. These developed 3-D integration approaches can be used to reduce the footprint and increase the power density for POL converters. This demonstrated that the power efficiency of both POL modules with integrated planar inductors can achieve above 87% at an operating frequency of 2 MHz and an output current of 15 A. Additionally, no obvious efficiency degradation was observed on the integrated POL modules after a certain number of thermal cycling from -40 °C to 150 °C.