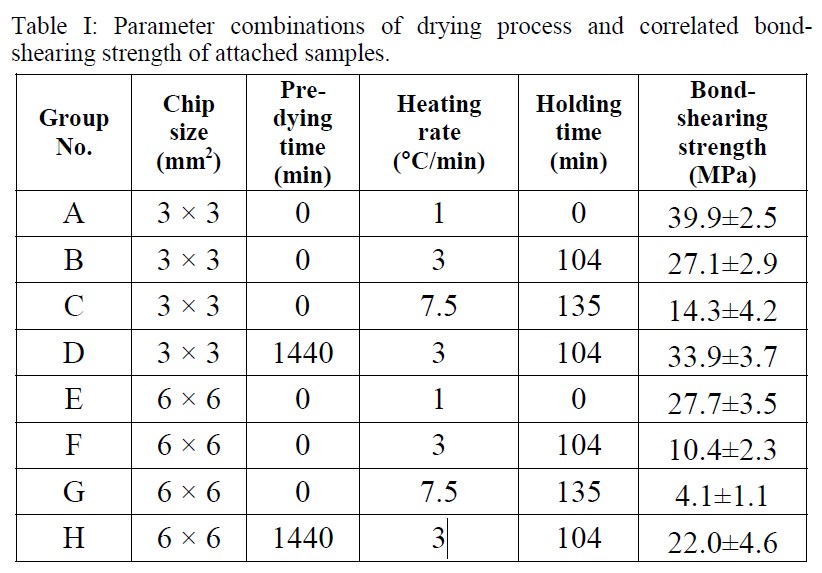

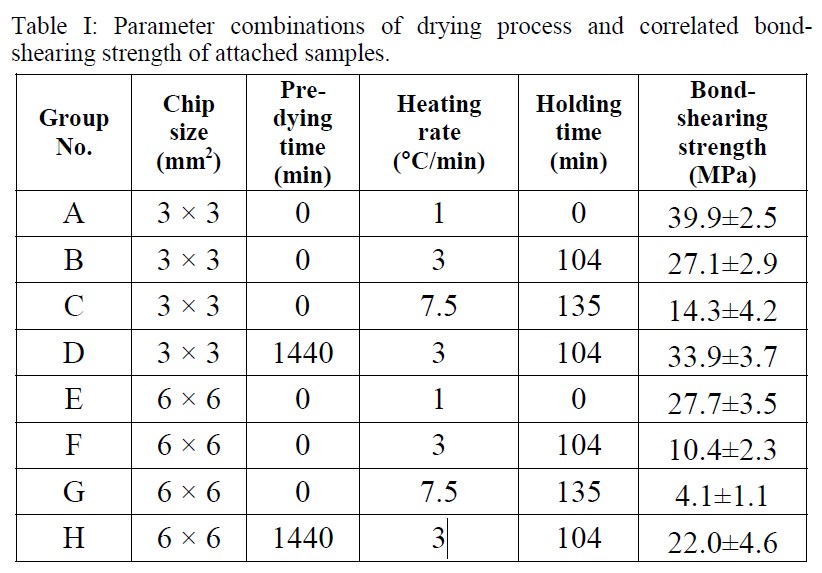

Fig. 1. Parameter combinations of drying process and correlated bond-shearing strength of attached samples.

Bonding chips by sintering silver particles (on the micron scale or nanometer scale) is widely believed to be stuitable for replacing soldering in the manufacture of high-performance power semiconductor devices and modules because sintered silver joints are better for heat dissipation and more reliable in temperature-cycling and power-cycling tests than soldered joints. Common raw materials used for the silver sintering process are in the form of paste consisting of silver particles mixed in an organic system of binders, surfactants, and solvents. In our recent studies, we developed a mathematical model based on the diffusion of solvent molecules and viscous-flow mechanics of a silver paste to show that drying of the paste in the bonding process is a critical step in determining the microstructural and mechanical quality of the bond-line. Our modeling results showed that stresses and strains generated in the shrinking silver paste were responsible for observed delamination and cracking in the sintered bond-line. In this study, we extended the modeling analysis to investigate the effects of heating rate on the bond-line quality. A numerical simulation algorithm of the model was developed to determine the time-dependent physical properties of the silver paste as it was being dried at different heating rates. The simulation results showed a strong dependence of the relative density of the sintered bond-line on heating rate. By lowering the heating rate, the relative density of the sintered silver could be increased. A higher sintered density would mean stronger bonding strength, and this was verified by our experimental data. The findings of this study can be used to optimize the manufacturing process that uses sintering of silver paste for bonding power semiconductor chips.

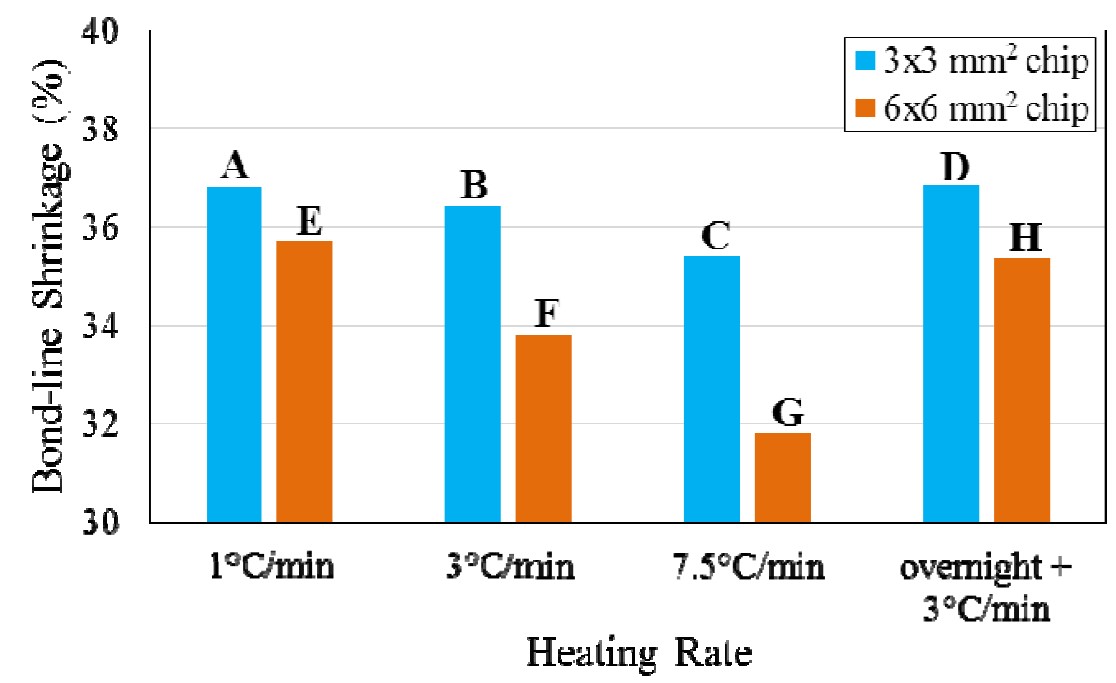

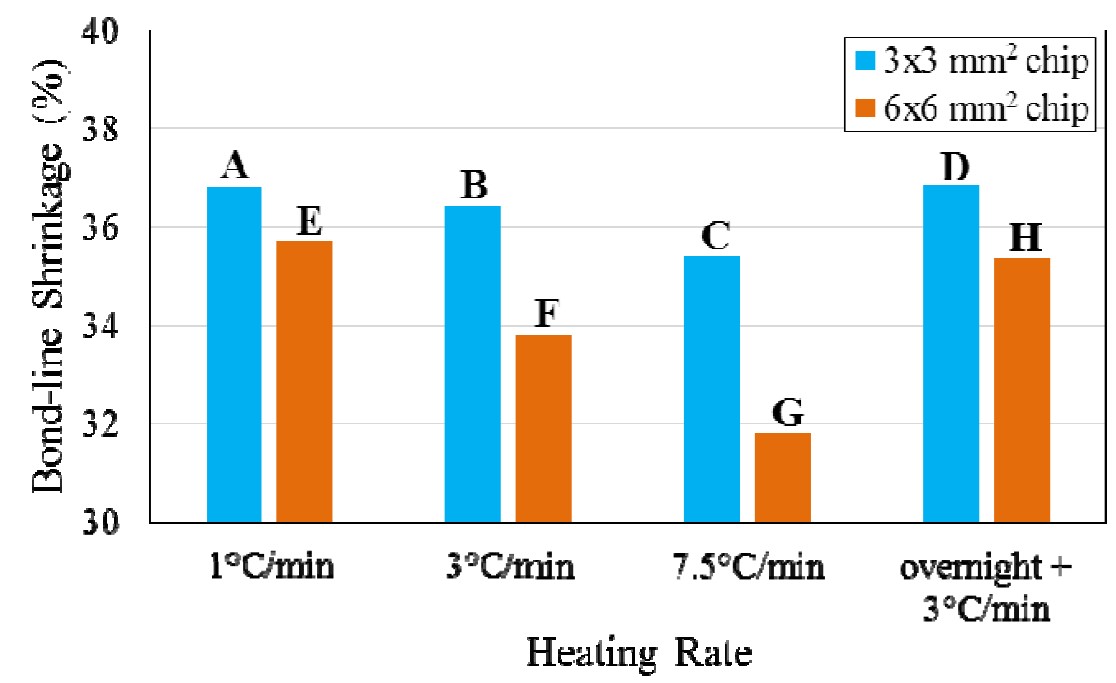

The effect of the heating rates of 1°C/min, 3°C/min, and 7.5°C/min on the bonding strength of sintered nanosilver joint was studied. A diffusion-viscous model was developed to analyze the stress-strain state inside the silver paste bond-line, and numerical simulations were carried out to determine the internal stresses and bond-line shrinkage during the drying process. We found that tensile stresses generated in the paste bond-line increase with the increasing heating rate and decreasing chip size. Storing samples at room temperature for an extended period of time helps to lower the internal stresses. The internal stresses reduce bond-line shrinkage, leading to lower relative green density of a dried bond-line, which in turn lowers the sintered density and the bonding strength.

Fig. 2. Simulated bond-line shrinkages after the various drying profiles.