LIBRARY

Very High Frequency Integrated Voltage Regulator for Small Portable Devices

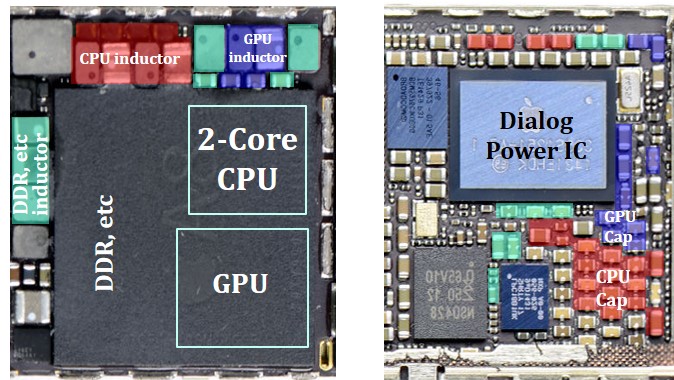

Power consumption would be reduced dramatically if the supply voltage could be modulated rapidly based on the power demand of each core. However, the voltage regulator in Figure 1 is unable to offer this feature because of their low switching frequency and the high interconnect impedance between the voltage regulator and the processor.

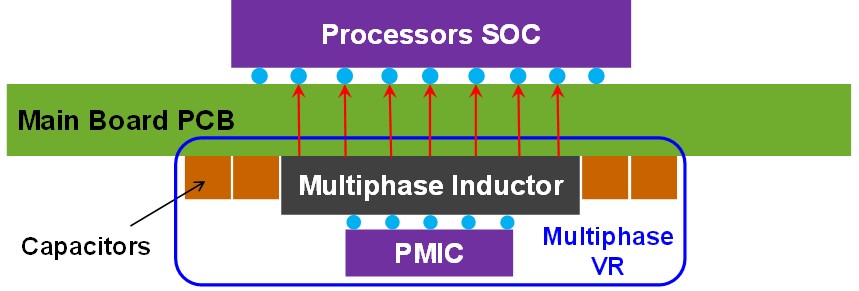

Integrated voltage regulators with high granularity, small size, near-load integration, and very high switching frequency have been successful in improving the efficiency of power delivery to multi-core processors, such as those implemented in Intel's Haswell and Broadwell processor. This work extends this concept to create the 3D integrated architecture in Fig. 2 for small portable devices. The converter is running at tens of MHz to track the core voltage. The multi-phase one-turn inductors are integrated into one magnetic core featuring a simple structure, ultra-low profile, small size, lateral non-uniform flux distribution, and air-gap free structure (to effectively confine very high-frequency stray flux). The inductor is designed with 0.5 mm thickness to fit the stringent space requirement of smartphones, and placed directly under the processor die to facilitate a short power delivery path. The inductor will be stacked with the power-management IC to save the footprint traditionally occupied by the passive components. In the case of Fig. 1 for example, a total footprint of about 100 mm2 can be saved.