LIBRARY

Integrated Switch Current Sensor for Shortcircuit Protection and Current Control of 1.7-kV SiC MOSFET Modules

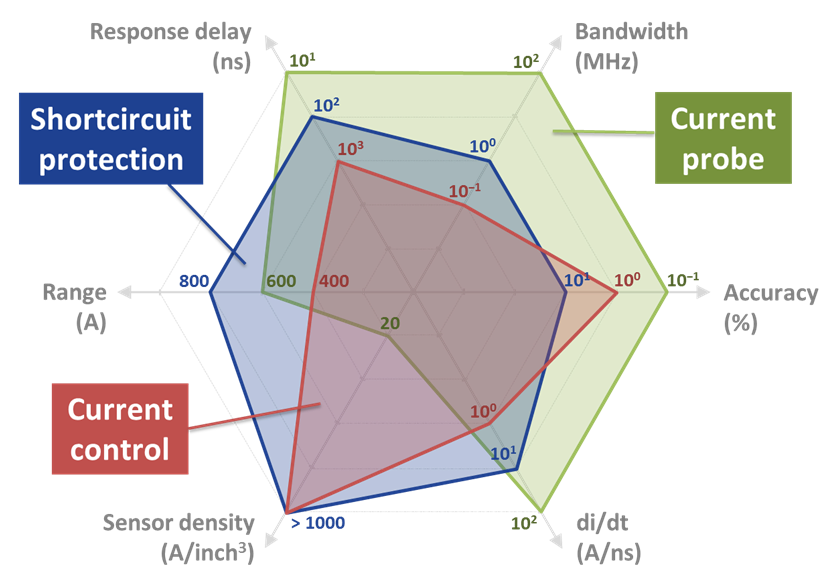

As previous research shows, DeSat protection does not suit for the SiC MOSFET modules. Direct measurement of the device current can be a better solution as long as the switch current sensor can provide a large enough bandwidth (BW), low response delay and fair accuracy. Rogowski's coil-based switch current sensor is able to meet the requirement for shortcircuit protection of the SiC MOSFET modules. This paper also designs the sensor for high accuracy targeting at current control, which request another set of specifications (Fig.1). The switch current provides more than enough information for current control. The excessive information can be used as sensor redundancy where higher reliability is brought. In medium voltage applications where Power Electronics Building Block (PEBB) based converters or multilevel converter are widely used, a switch current sensor can ease the diagnostics of a damaged device, or help monitoring abnormal devices. However, challenges do exist mainly due to the high dv/dt and the non-ideal performance of the integrator.

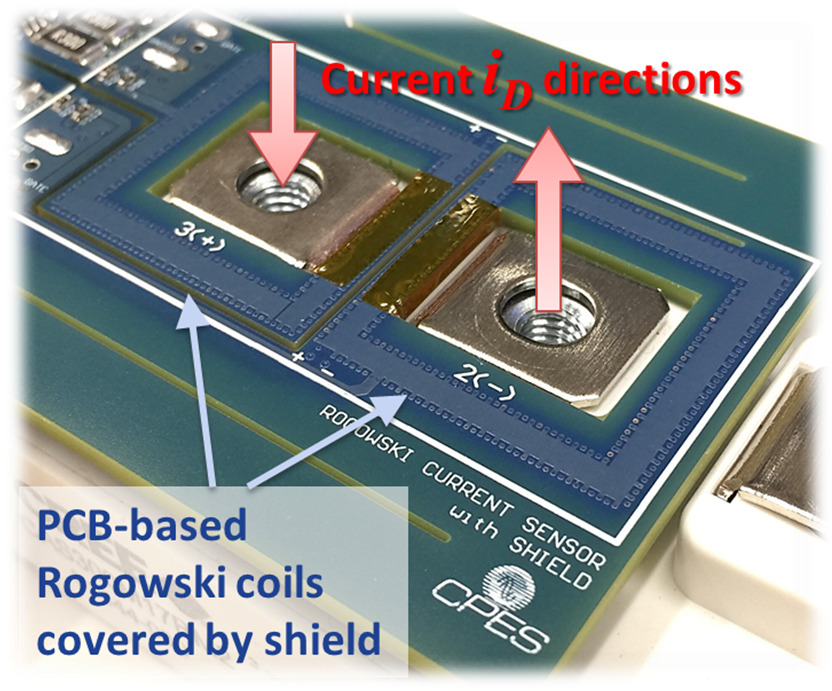

As shown in Fig.2, the final sensor prototype was integrated together with the gate driver on the same board, and validated with excellent performance.