LIBRARY

A High Efficiency Isolated Regulated 48 V Bus Converter with Integrated Magnetics

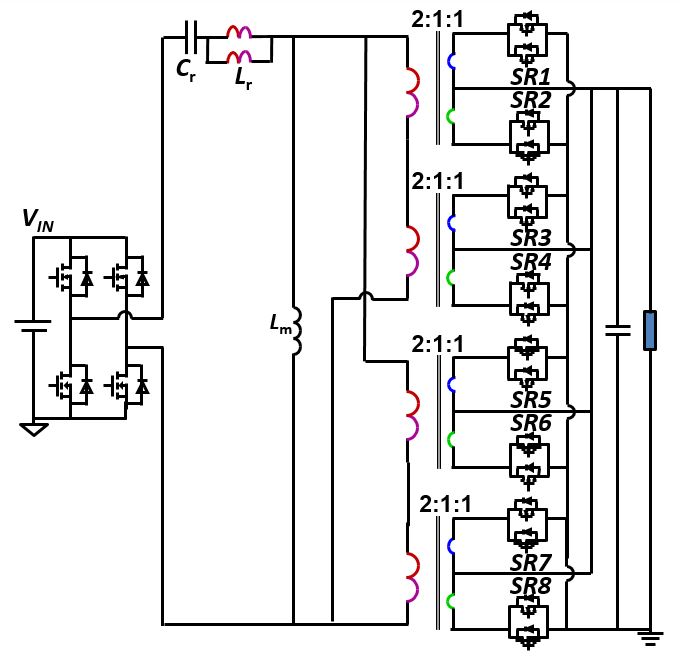

In this work, a single stage LLC converter with integrated magnetics is proposed for 48 V/12 V-1 kW bus converters which can provide both regulation and isolation. The current practice for dc-dc bus converters is operating at low switching frequencies in a range of 100-200 kHz, with a power density below 400 W/in3. For higher power density, this converter is able to operate with 10 times higher frequency than standard industry practice. Due to its soft switching properties, an LLC converter is most suitable for high-frequency operation for all devices by which higher efficiency and power density can be realized. For high output current and low voltage dc-dc converters, the matrix converter has proven a perfect candidate as it distributes the secondary current among different outputs to reduce the total conduction loss.

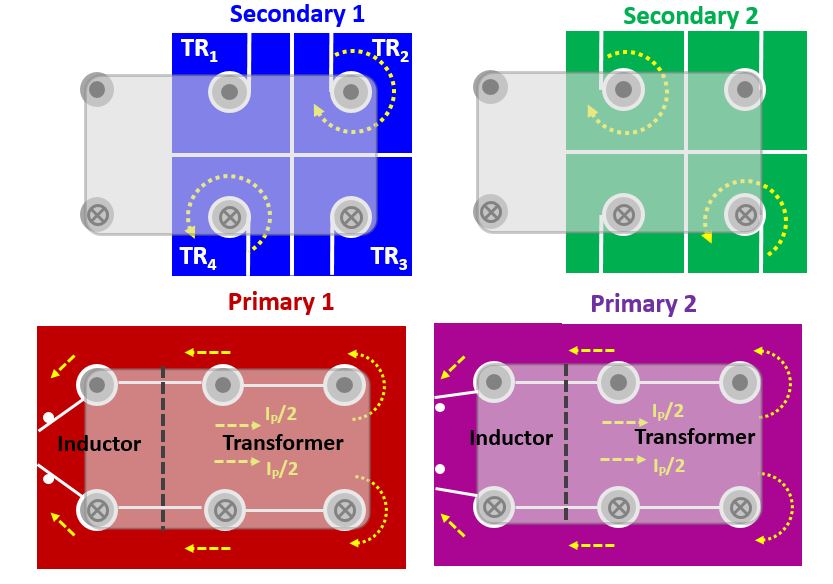

In this work, two matrix transformers with two transformer outputs each are used to deliver a 1 kW output power. The two transformers are connected in parallel from both primary and secondary windings as shown in Fig. 1. The primary windings are arranged in a way that integrates the parallel transformers with one core structure.

To achieve output voltage regulation, the resonant inductor must be designed to a specific value in order to have the required regulation capabilities. A novel magnetic structure is proposed wherein the transformer primary windings are extended, and a magnetic core is added to produce a controllable leakage inductance which can then achieve the regulation capabilities. The shared winding will result in lower losses of the resonant inductor. The proposed printed circuit board winding arrangement is shown in Fig. 2. A prototype is developed for the proposed converter achieving a power density of 800 W/in3, with an estimated efficiency more than 97 percent higher than all available industry practices.