LIBRARY

A Synchronous Distributed Control and Communication Network for SiC-Based Modular Power Converters

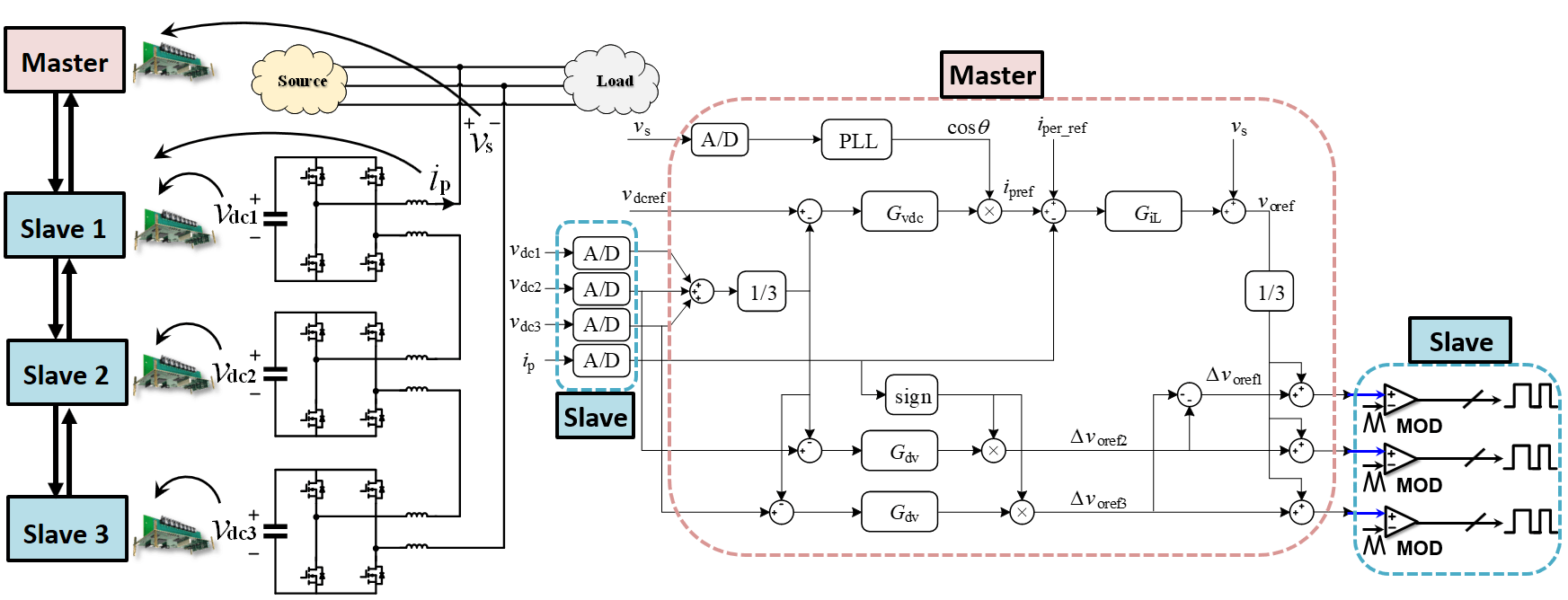

with linear daisy chain topology. The custom-made controller hard- ware is designed at CPES, based on a TI TMS320 DSP and an Altera MAX 10 FPGA. The closed-loop control algorithm is mainly implemented in the DSP, and the communication protocol is mainly implemented in the FPGA. In addition to the communication network between the master controller and the slave controllers, there is also communication inside each node. For example, in the slave node, the slave controller communicates with four gate drivers and two sensors, including one current sensor to measure the inductor current of the PEBB and one voltage sensor to measure the dc capacitor voltage of the PEBB. All of the sensing data will be transmitted to the master controller for the closed-loop control.

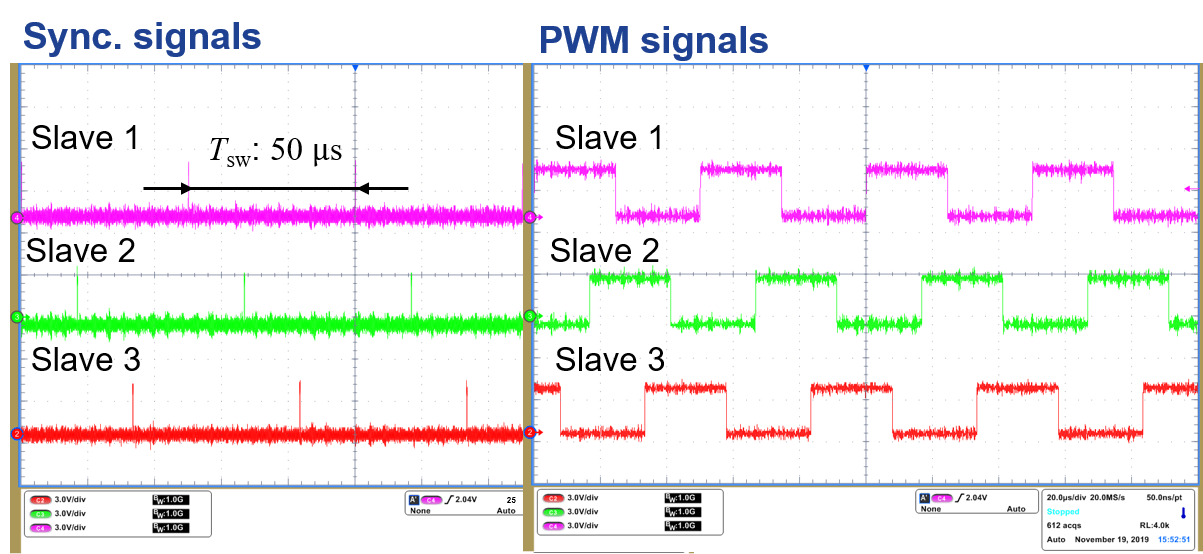

Since each PEBB is controlled by an individual controller, the synchronization among all of the controllers needs to be realized for the converter operation. The synchronization accuracy for four nodes is 25 ns. Based on the synchronization, the interleaved PWM waveforms for the three slaves are shown in Fig. 2. On the left is the trigger signal of a switching cycle for the three slaves, and on the right is the PWM waveform. The switching frequency for each PEBB is 20 kHz, and the communication frequency is 120 kHz.

In summary, a synchronous distributed control and communication protocol is designed and verified for a SiC-based modular power converter. A new synchronization method based on the oversampling clock and data recovery syntonization and PTP-based synchronization is implemented in the system. The synchronization can be well controlled with the maximum synchronization accuracy of 25 ns among four nodes. A control and communication frequency of 120 kHz is realized with a custom-defined packet and protocol.