LIBRARY

Insulation Online Monitoring for Critical Components inside SiC based Medium Voltage Converter Prototype

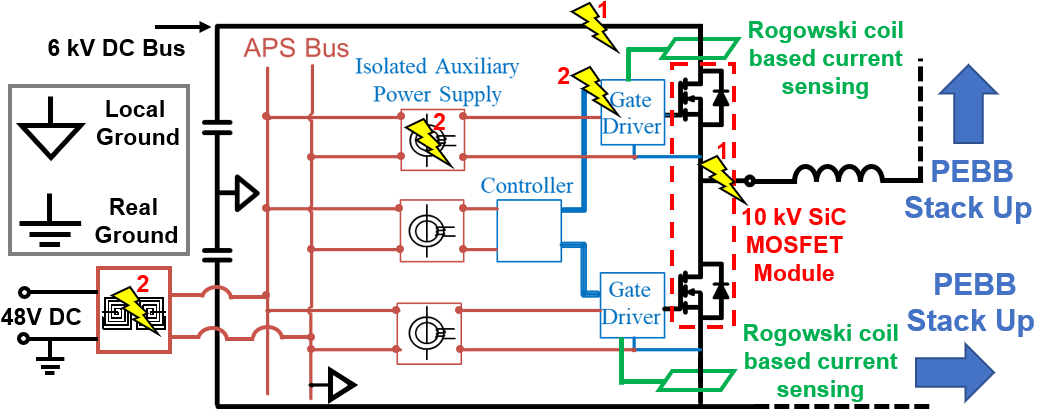

If surface discharge occurs on the power terminals (regions marked as 1 in Fig.1), on the one hand, it could introduce significant overvoltage to module power or driving terminals and thus dam- age the power devices. On the other hand, it could generate radiated noise, which makes the nearby sensing circuitry read incorrect measurements. Meanwhile, surface discharge on sensitive circuitry, like the driving and auxiliary power supply circuits (regions marked as 2 in Fig. 1), can destroy the ICs directly leading to the catastrophic fail- ure of the entire converter. In summary, online insulation monitoring for possible surface discharges can have great value for converter maintenance and safety operations.

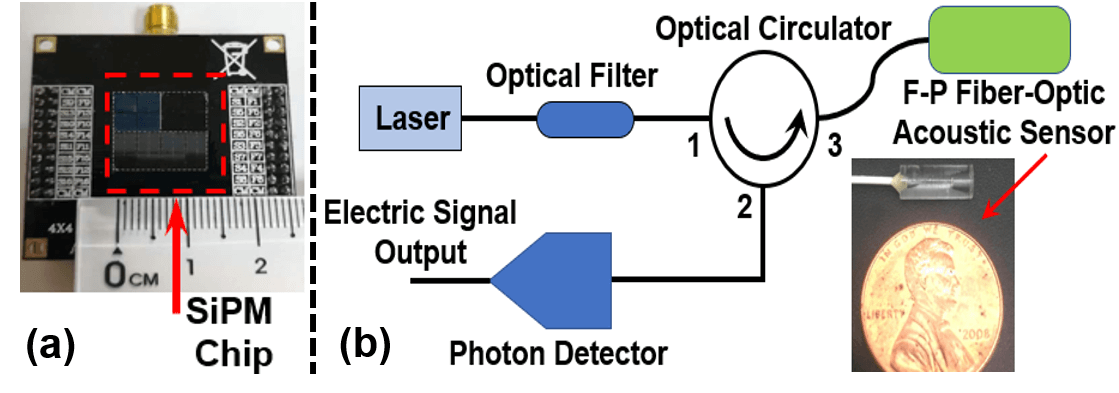

Two novel types of surface discharge sensors are proposed in this paper. The silicon photomultiplier (SiPM)-based optical partial discharge (PD) sensor is shown in Fig. 2(a), while the Fabry-Pérot (F-P) fiber-optic acoustic PD sensor head with its detection system schematic is shown in Fig. 2(b). They are both compact in size with good isolation level and high immunity to the on-site EMI.

Based on the experimental test results, both sensors can be placed inside the converter and thus realize the surface discharge online monitoring by capturing either the acoustic signal or the photons that are generated by the discharge events. The SiPM-based optical PD sensor has a relatively simple structure and can be integrated easily. However, it has limitations such as low background light leakage inside the converter. The F-P Fiber-Optic acoustic PD sensor has fewer limitations and can also be applied for PD localization, if a sensor array is implemented. The localization accuracy about 20 cm can be achieved, if the sensor array is properly designed and installed. However, it contains more parts in the detection system, which leads to higher cost and more issues for system integration.