LIBRARY

Gate-Driver Integrated Junction Temperature Estimation of SiC MOSFET Modules

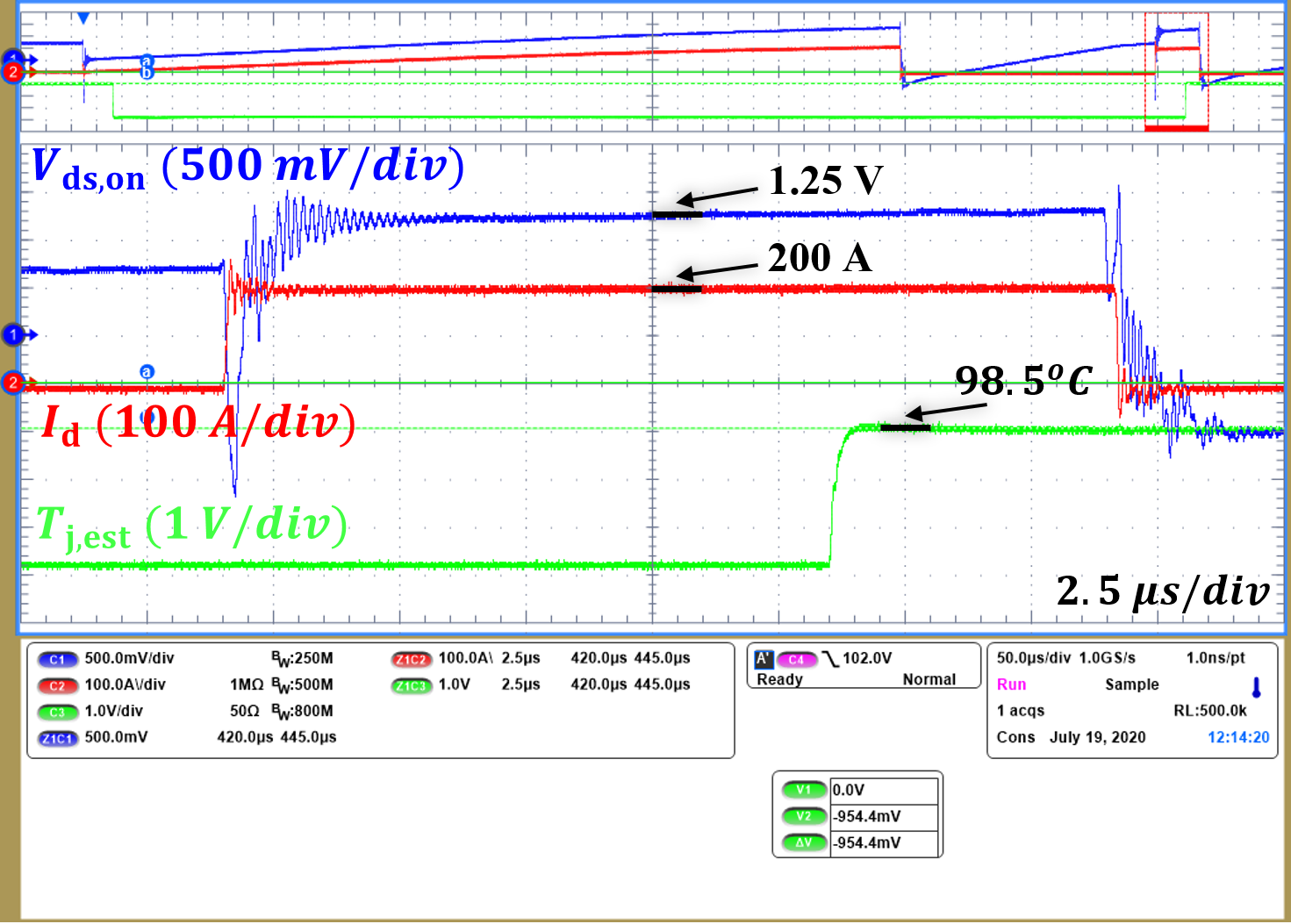

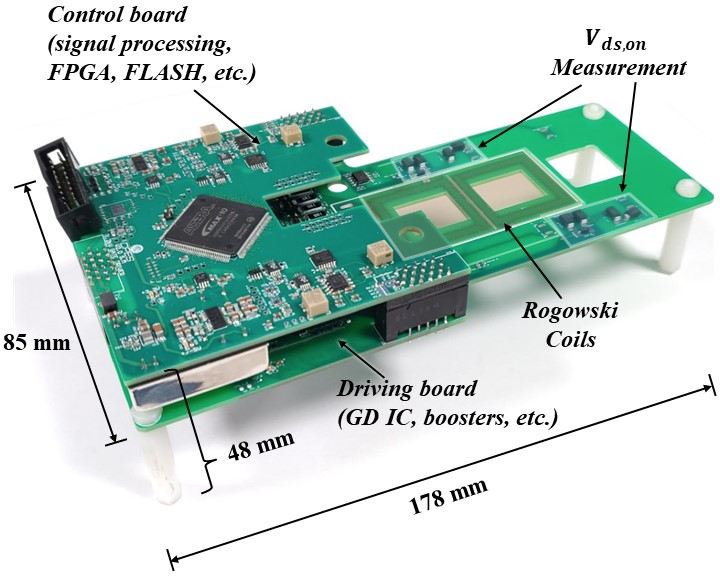

Intelligent gate driver is developed containing described measurements and is shown on Fig. 1. Rogowski coils are utilized for switch current measurement exhibiting high bandwidth and accuracy while not imposing on power density. So-called two diode circuit is utilized as an on- state voltage measurement sensor due to benefits such as high blocking capability, no offset problem, temperature independency, low losses, great accuracy, and sensitivity. Online junction temperature estimation will be performed with the aid of Field Programmable Gate Array (FPGA), that will sample current and voltage information at the same time. Based on the calibration results of the device stored in the Flash memory (temperature look-up table) on the gate driver, FPGA will assess and compare voltages and currents, thus returning estimated junction temperature. Fig. 2. shows temperature estimation results during double pulse test with pre-set to temperature of 100° C. Accuracy of the method throughout the whole tested temperatureis higher than 96 %, with absolute owing great promise.

Furthermore, a generalized junction temperature monitoring procedure is proposed, avoiding often complicated calibration procedures. The accuracy of this approach is relatively high, improving on and avoiding tremendous errors that would occur by implementing datasheet extracted thermal map and relying on temperature estimation by datasheet.