RESEARCH

Active Standard-Cell Integrated Power Electronics Module (SC-IPEM)

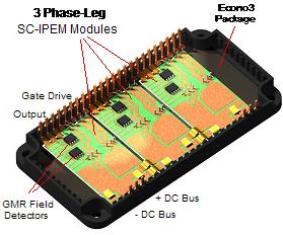

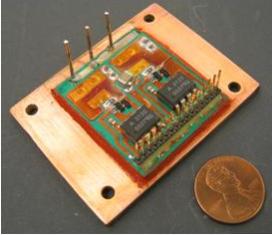

flip-chip-on-flex SC-IPEMs.

Several CPES technology advances are being incorporated into the active SC-IPEM design. The flip-chip-on-flex and embedded power technologies have been adopted to eliminate all wire bonds in favor of a planar interconnection scheme that minimizes dangerous voltage transients caused by undesired parasitic inductances. In addition, the flat upper surface is valuable for mounting gate drives, sensors, and cooling components to extract extra heat from the top side of the module. Such advances contribute to reducing the module size while increasing its long-term robustness.

Other advanced technology features that are planned for demonstration using the active SC-IPEMs include new types of integrated current sensors and advanced gate drive features. Two examples of the new gate drive features are active dv/dt control during switching transients to reduce EMI, and active thermal control to increase module reliability by reducing temperature excursions of the power switches.

The IPEM planar interconnect technology shows significant promise for improving the performance of future generations of commercial power modules. This has been confirmed by recent feedback from CPES industrial sponsors, who recognize the potential value of these features. There are also clear signs in new power module product offerings that trends toward higher levels of feature integration are continuing and perhaps even accelerating.

However, the rate of this technology transfer process has been slowed by power electronics design engineers who are hesitant to give up their ability to supply their own fully customized gate drive, sensor, and protection functions in order to purchase integrated power modules that provide these advanced features in standardized combinations. There is also concern about the long-term reliability of these new integrated features based on historical problems with early generations of power-IC gate drive chips that predate CPES, but still live on in the memories of some customers. Successes with new generations of power modules that include advanced features are gradually overcoming these obstacles to immediate customer acceptance, but engineering conservatism and high component cost sensitivity continue to constrain the rate of IPEM technology penetration.

phase-leg SC-IPEM.