RESEARCH

PCB Embedded Magnetics Core with Improved Flake Materials

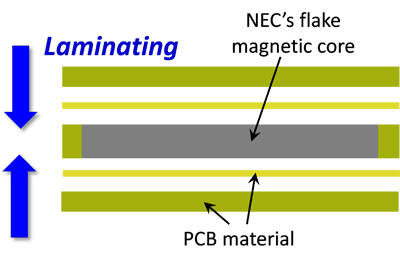

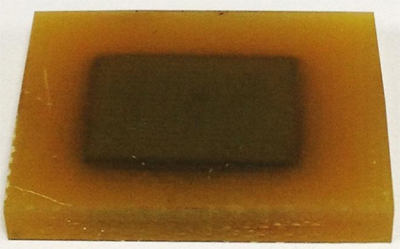

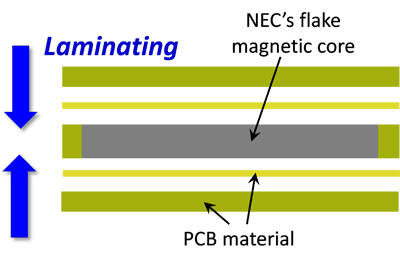

In previous PCB integration techniques, the magnetic materials either have a very low permeability, or are difficult to be shaped with low temperature processing. The SENFOLIAGE metallic flake material developed by NEC/Tokin improves the permeability to several hundreds, which is much higher than that of the conventional flake material. By aligning the small flake pieces as shown in Fig. 1, the eddy current loss in megahertz is reduced dramatically. More important, the core material is very easy to be patterned. The laminated multi-layer PCB with SENFOLIAGE plate is proposed as Fig. 2 and fabricated as Fig. 3. The surface copper on the PCB can be used to build the windings and the circuit connection. The SEM image in Fig. 4 shows the lamination of FR4 and magnetic core is cohesive and no delamination is observed. Therefore, the SENFOLIAGE is compatible with the conventional PCB process and it is good candidate for PCB integration of high frequency converters.