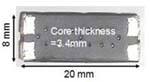

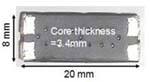

Fig. 1. Vertical flux coupled inductor structure.

Low profile integrated Point-of-Load (POL) converter is today's industry trend for portable electronic applications. Magnetics is the major challenge and bottleneck for achieving low profile high power density integrated POL. So, how to design a low profile magnetic becomes one of the key technologies for integrated POL. Inverse coupling is one of the possible methods to reduce inductor size due to the dc flux cancelling effect.

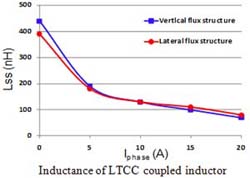

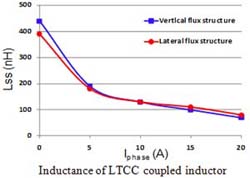

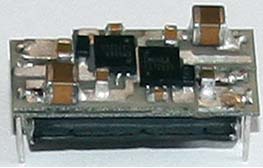

Based on low temperature co-fired ceramics (LTCC) technology, low profile coupled inductor structure with lateral flux patterns is proposed to reduce inductor size. Comparing with vertical flux coupled inductor structure the lateral flux coupled inductor structure can have higher inductance density. The power density of a 1.5MHz, 5V to 1.2V, 3D integrated buck converter with LTCC lateral flux coupled inductor substrate is as high as 700W/in

3.

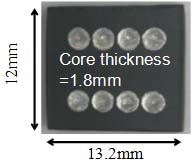

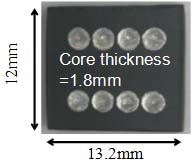

Fig. 2. Lateral flux coupled inductor structure.

Fig. 3. LTCC coupled inductor with vertical flux.

Fig. 4. LTCC coupled inductor with lateral flux.

Fig. 5. Inductance of LTCC coupled inductor.

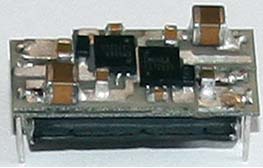

Fig. 6. Integrated POL with LTCC coupled inductor