LIBRARY

Design and Optimization of a High Performance Isolated Three Phase AC/DC Converter

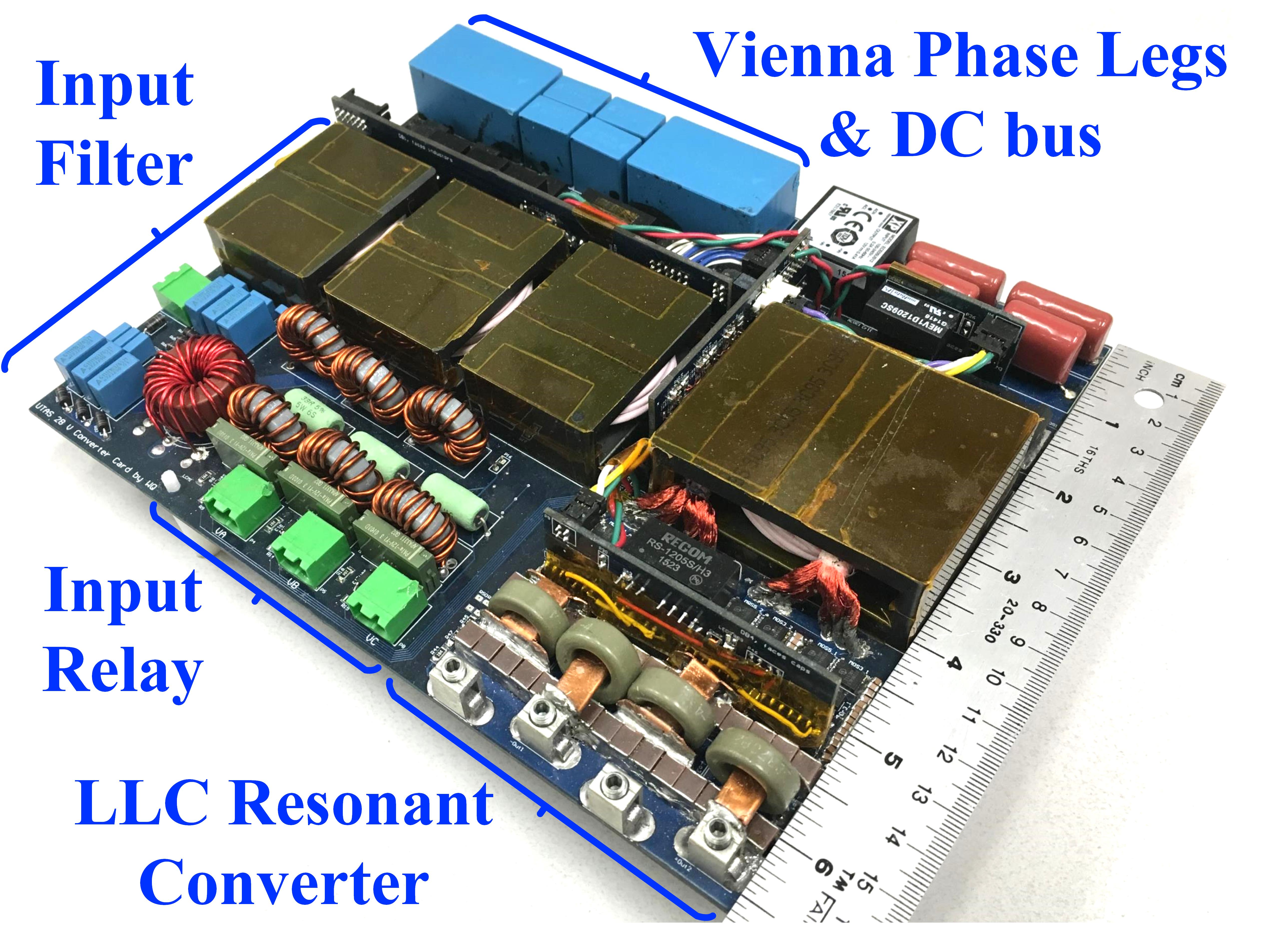

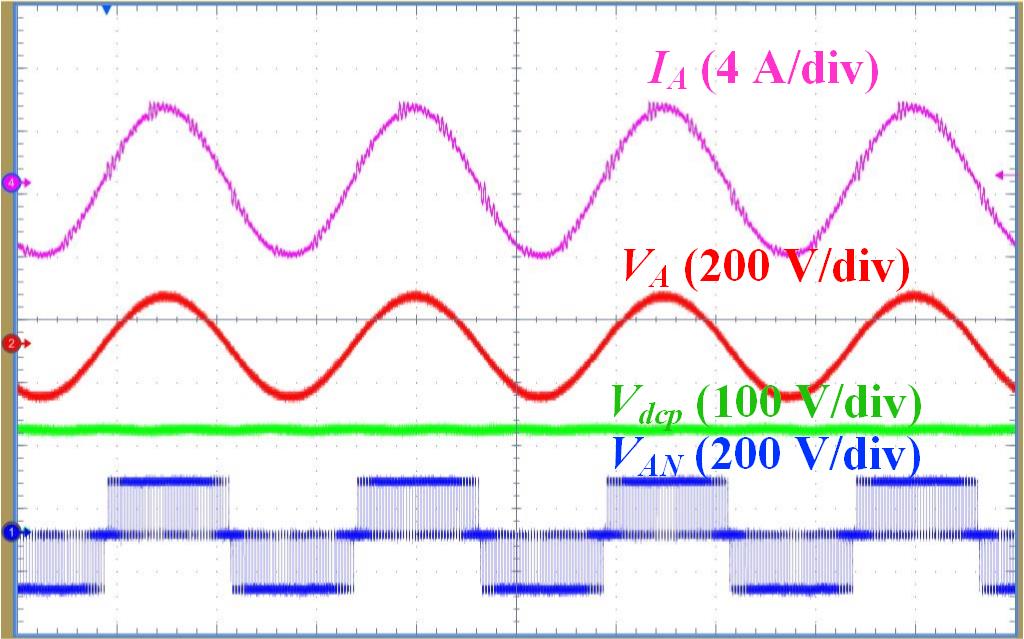

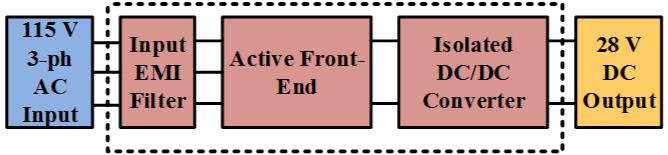

A two-stage structure (shown in Fig. 1), where an active front-end (AFE) converter is joined with an isolated DC/DC converter, was employed in this design. The AFE stage converts a three-phase variable frequency (360 Hz ~ 800 Hz) AC voltage (115 Vrms) into a regulated DC voltage while perform-ing a power factor correction for the inputs. An isolated DC/DC stage con-verts internal DC bus voltage into output DC bus voltage (28 V) while providing galvanic isolation. Input EMI filters were added to meet EMI standard. A complete design and optimization method was developed in search of the relationship between the converter rated power, full load loss and converter size of this multi-converter system. A 1.2 kW converter proto-type (shown in Fig. 2) was constructed based on the design and optimization results. The 1.2 kW free convection cooled prototype exhibits a 97.1% full load efficiency and a 22 W/inch3 power density. The compliance of EMI standards and power quality standards was verified experimentally.