RESEARCH

Characterization of Low-Temperature Sintered Ferrite Laminates for High-Frequency Point-of-Load (POL) Converters

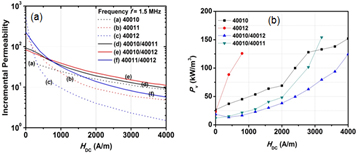

Low-profile magnetic components and their associated integration techniques are desirable for the design and fabrication of highly integrated point-of-load (POL) converters working at high frequencies. The multilayer low-fire ferrite inductors can be fabricated as the magnetic su-strate in an integrated POL converter with the active components on top. The permeability and core loss density under high DC bias are of special interest, and were characterized on different low-fire ferrite laminates. The microstructures and chemical compositions of sintered multilayer ferrites were investigated in order to understand the difference in the magnetic properties among those samples.

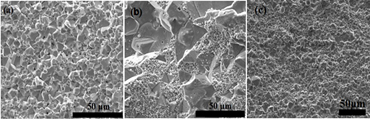

In this study, the mixed laminates 40010/40011, 40010/40012, and 40011/40012 in alternating layers in a 1:1 ratio were co-fired at 885°C under a prolonged sintering profile. All the resulting laminates illustrate uniform microstructures and homogeneous chemical compositions through elemental inter-diffusion and the assistance of the redistribution of Bi2O3-rich liquid during sintering. Compared to the 40010 material, higher permeability and lower core loss density are obtained in a mixed 40010/40012 laminate, where the DC bias is in the range of 0 to 4000 A/m.

The 40010/40012 ferrite laminate has been used for inductor fabrication and integrated into a POL module achieving high efficiency of 81% at 5 MHz. The developed low-profile ferrite inductors demonstrate a unique method for hybrid power electronics integration and realize a size reduction for high-frequency POL converters. Further investigation of these materials and associated techniques could potentially enable a system-in-package approach for power electronics application.