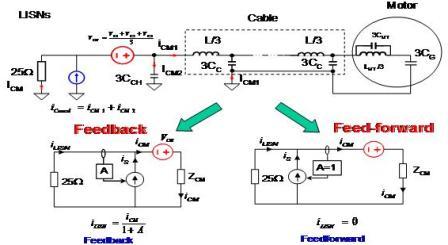

Passive EMI filters are widely used in power electronics systems to suppress EMI noise. Because of the switch-mode operations of the power electronics circuits, the EMI is usually very high. As a result, the size of EMI filter is usually up to ¼ of the whole system. In order to improve the power density, EMI filter size should be reduced. In order to reduce EMI filter size, active EMI is investigated to reduce CM noise of the power electronics systems. There are two ways to reduce CM noise using active filters. One is to do CM noise voltage cancellation and the other is to do CM current cancellation. CM noise voltage cancellation is achieved by generate a CM voltage which has the same amplitude inversely series with the original CM noise voltage. The total effects are the cancellation of the CM noise. The CM current cancellation can be implemented by forward and feedback methods. For forward current injection, a current which has the same waveforms as the CM current is injected to the input of the system and the injection point is before the current sensing point. The current amplifier has the unit gain to in the active filter. The net effects of the current injection are to provide a path to bypass CM noise. For the feedback method, the CM current is injected after the current sensing point. The current amplifier has large gain to guarantee the enough cancellation of the CM current.

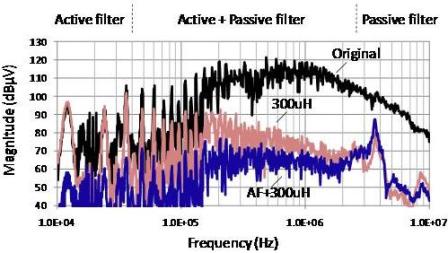

The experiments are carried out in a motor drive system. A hybrid EMI filter is built. The hybrid EMI filter is composed of a passive and an active EMI filter. The passive filter attenuates the CM noise to a level that active filter can further attenuate it. The experimental results show that there are up to 50dB CM noise reduction at low frequencies. Sine noise can be reduced by 300 times, the inductance of the CM EMI filter could be much smaller.