LIBRARY

High Temperature SiC Power Module Electrical Evaluation Procedure

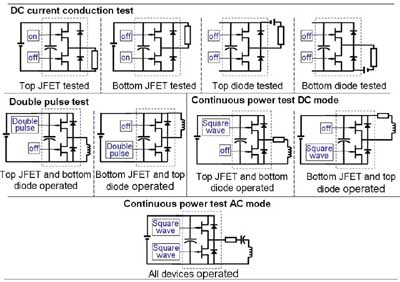

Potential defects may exist in the power module packaging during the fabrication process. In the electrical evaluation tests, failures can happen due to one or more of these defects. If a power module directly electrically evaluated and failed in the continuously power test, the causes of the failure are difficult to be identified. In order to reduce the risk and fast detect potential defects, the evaluation should follow a systematic procedure. Once the power module is fabricated, the static I-V characteristic needs to be evaluated first. The following evaluation step is dc current conduction test, which examine the integrity and quality of die-attachment, connection to external circuit and wirebond quality. The double pulse tests can be then conducted to examine the switching functionality of the devices with rated voltage and rated current at rated junction temperature. Finally, continuous power test should be conducted if no failure happened in the previous tests. The tests schematic is shown in Figure 1.

A successful continuous power testing on the prototype module demonstrates the systematic evaluation procedure can reduce the risk of failure and enhance the multi-chip module development.