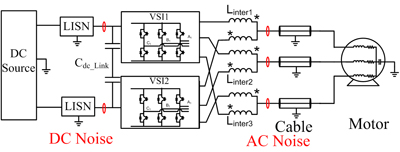

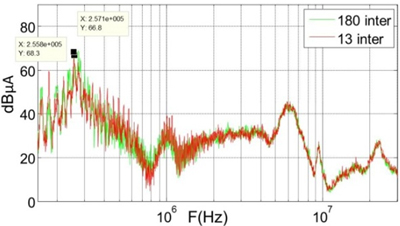

Fig. 1. Interleaved 2L VSI DC-fed motor drive system.

An adjustable-speed motor drive with a voltage-source pulse-width modulation inverter with long cables (shown as Fig.1) brings the EMI issues to the motor drive system [1]. Usually EMI filters are the part of the system that makes both the AC and DC side meet the EMI requirement (such as DO160E standard), which takes a large portion of the system weight. To improve the system power density and reliability, paralleled and interleaved converter topology is commonly used. By phase-shifting the PWM switching cycles of individual converters with an appropriate angle, the total voltage ripple due to PWM switching at the ac terminal can be reduced. Because of the reduction of the ripple voltage, the ac line harmonic current can be reduced. As a result, the use of this PWM technique has the potential to reduce the size of the converters passive components and increase power density.

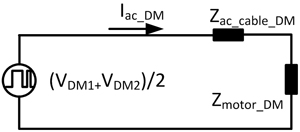

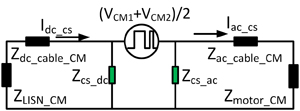

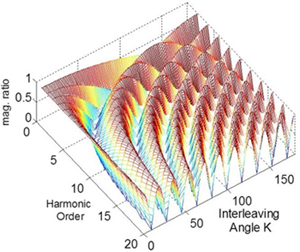

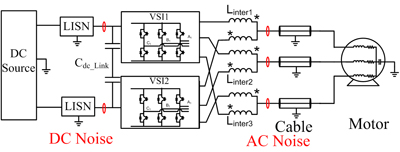

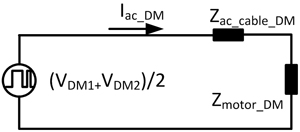

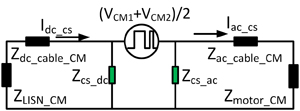

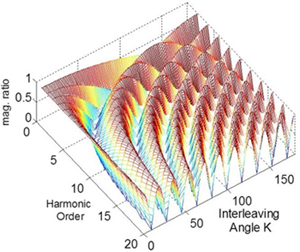

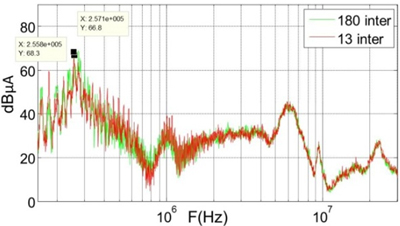

To study the impact of interleaving on system EMI performance, the equivalent circuit is given as Fig.2, which shows that interleaving will change the noise sources for both CM and DM noise. The impact of interleaving can be predicted using a double Fourier integral analysis and the selection of optimized interleaving angle is related to the system noise propagation path impedance as shown in Fig.3. Both simulation and experimental results prove that by using an optimal interleaving angle the EMI noise can be reduced by 10~12dB in the impedance resonant frequency range, which can reduce the EMI filter size significantly.

Fig. 2. (a) Equivalent circuit for converter output DM and CM noise of dc-fed system with interleaving: DM equivalent circuit.

Fig. 2. (b) CM equivalent circuit.

Fig. 3. Voltage noise source magnitude reduction on different order harmonics of interleaving with different interleaving angle.

Fig. 4. Experimental ACCM noise (180° interleaving: green and 13° interleaving: red).