LIBRARY

Thermal Characterization of Planar High Temperature Power Module Packages with Sintered Nanosilver Interconnection

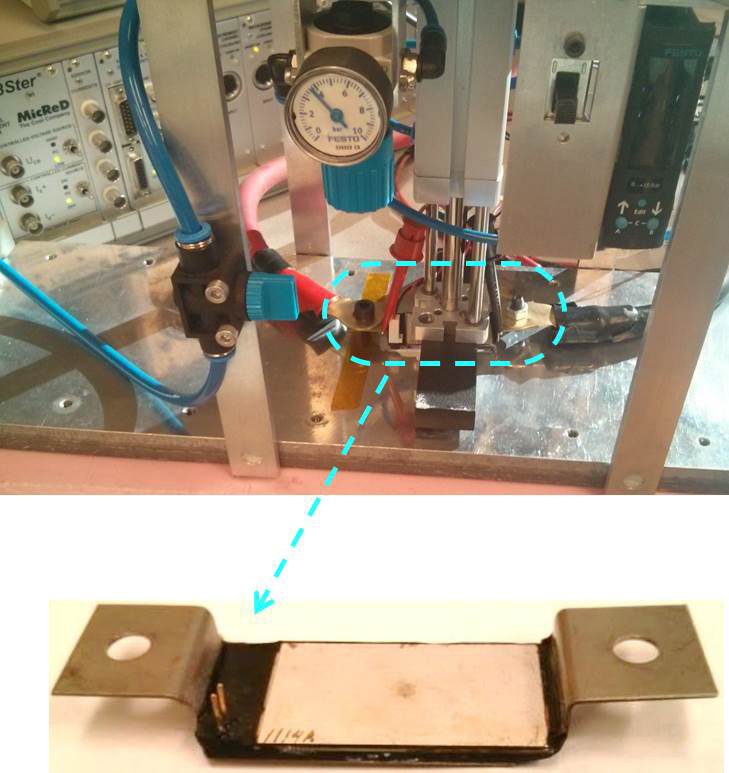

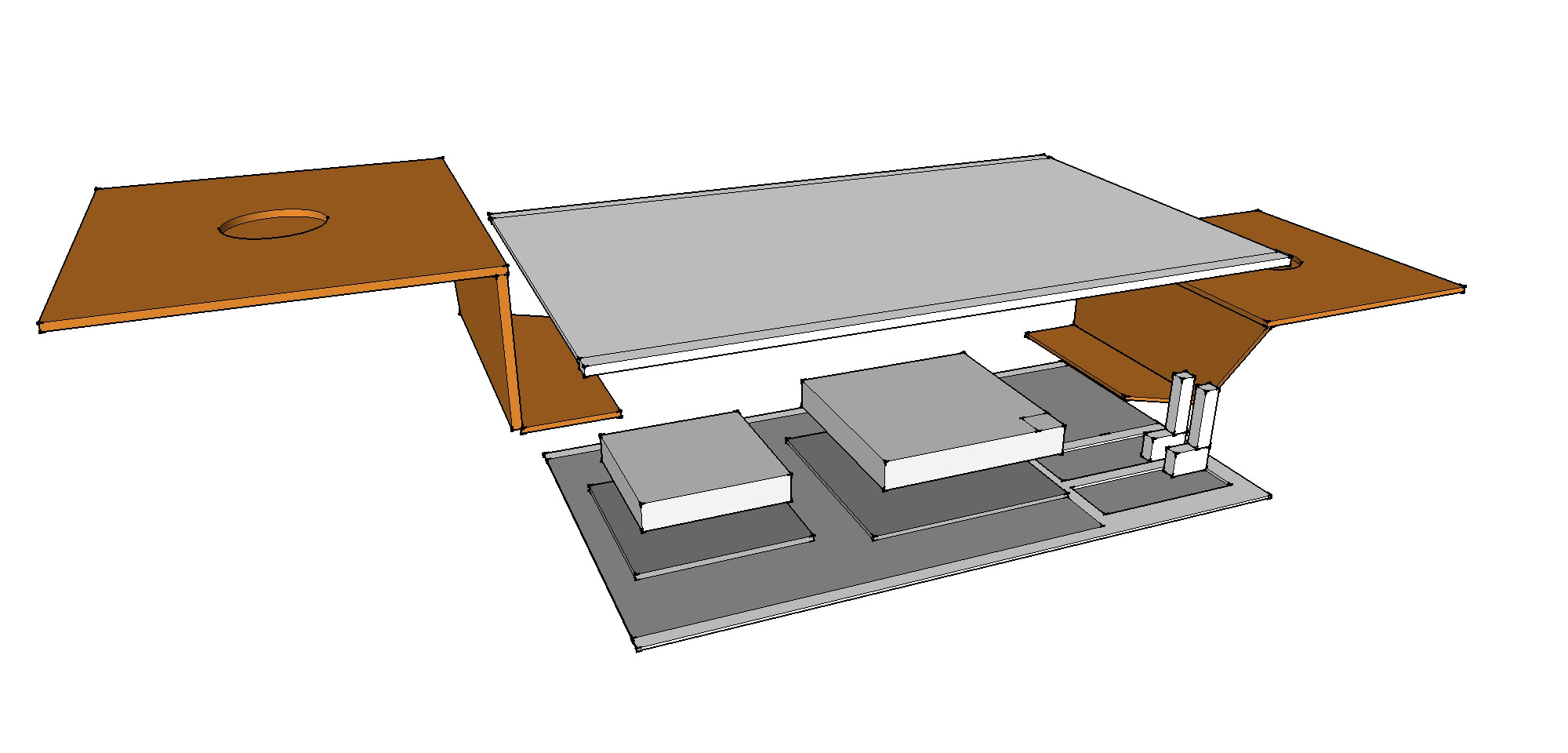

In this paper, we outline the fabrication of functional double sided power module switching unit utilizing LTJT sintered silver for each interface. This symmetrical structure replaces the low thermally conductive encapsulation, normally used above attached devices, with an additional substrate which should theoretically half the package thermal resistance. Thermal resistance measurements and techniques for single sided power module packages are well documented and used extensively by module manufacturers. However, a three dimensional structure which allows for heat transfer through both the top and bottom substrates presents a new challenge for characterization.

In this paper, the thermal characteristics of a functional double sided power module were measured in all possible cooling scenarios. These measurements utilized a dual interface thermal insulating material (TIM) technique developed by MentorGraphics. The resulting improvements in thermal resistance of the sintered silver power module package and constructed thermal simulation models will be discussed for each cooling configuration.