LIBRARY

Improving the Efficiency and Dynamics of 3D Integrated POL

One unique property of the non-uniform flux inductor is its variable core loss at different load conditions. Although the total flux is clamped by the voltage-second applied on the core, and independent to the load current, the flux density (BAC) distribution changes a great deal at differ-ent load conditions. At heavy load conditions, BAC is pushed out by the strong HDC near the vias; while at light load conditions, the major portion of BAC is concentrated in a small volume around the vias. As a result, the core loss density (Pv) distribution has a similar pattern as BAC: at light load conditions, the large Pv value is located in a small core volume near the vias, which dimin-ishes its core loss production (the product of Pv and core volume). This special property, along with the smaller HDC at light load conditions, means a smaller core loss at light load than at heavy load conditions.

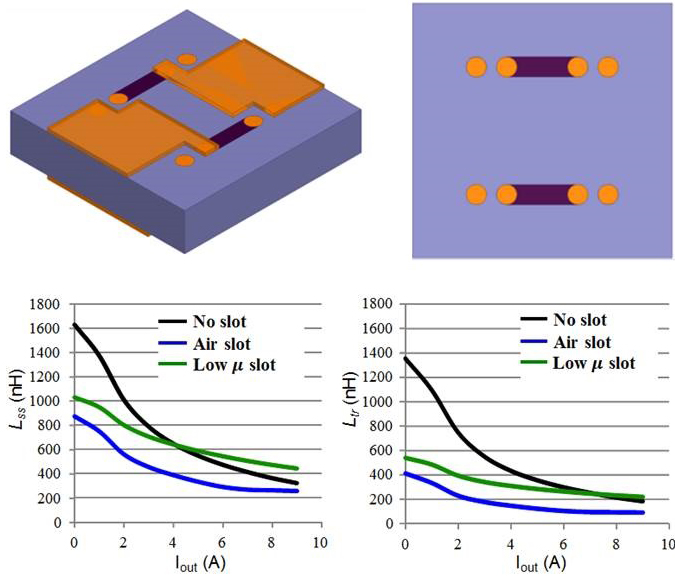

For the two-phase coupled inductor, a structure with a slot between two phases and low permeability filling material is proposed (as shown in Fig. 2). By controlling the permeability of the filling material, the non-linearity of Lss and Ltr can be controlled to achieve a balanced trade-off between the efficiency and dynamics of the POL module. The low permeability filling material is characterized, and the extra core loss it induces is analyzed, showing that the low permeabil-ity material contributes only a very small portion of the total inductor core loss due to its small volume portion.