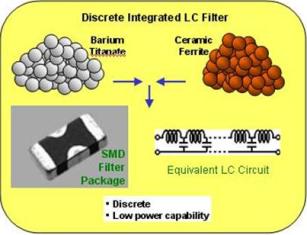

Multi-ferroic composite materials are artificially designed and synthesized to have tailorable dielectric and magnetic properties such that capacitive and magnetic elements can be fabricated on the same material platform. Successful transfer of this technology would enable manufacturers of electronic products to shrink the size and weight of passive components in an electronic system, reduce the fabrication complexity, and potentially lower cost. In today's power electronics packages and modules, passive components such as inductors and capacitors tend to be bulky because of the requirement that they must be able to handle large amounts of energy, and therefore take up a disproportionate amount of real estate on the mounting substrate. The existing method of integrating passives involves assembling separate layers of ferroelectric materials (e.g., barium titanate) with high dielectric constant (high-k) for the electrostatic energy storage, and a ferrite core having high magnetic permeability (high-m) for the magnetic function. This imposes physical, mechanical, and processing limitations, while not substantially contributing to volume reduction. Thus, advances that can miniaturize passives, as enabled by CPES's multi-ferroic composite technology, will lead to significant reduction in the size and weight of electronic products.

However, successful transfer of CPES's multi-ferroic composite technology faces enormous challenges. For one, there are still many unanswered scientific questions concerning design, synthesis, and fabrication of multi-ferroic materials because of a combination of synthesis and processing issues and application requirements having competing demands. Lack of in-depth understanding on the fundamentals of these materials hampers the development of material systems with optimized multifunctional properties to meet specific application needs. The second challenge facing the successful technology transfer comes from the generally slow acceptance by system engineers to new materials or device technologies. This may be because the adaptation of a new materials/component technology would require rethinking of system-level designs to fully realize the advantages and opportunities presented by the new technology.